News

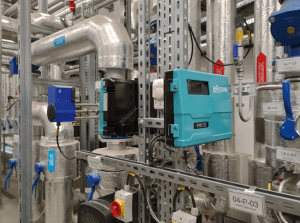

The process signals were routed to a PLC controller, which is responsible for regulating the entire process. The data is then transferred to a visualization system, giving operators full insight into the operation of the installation.

This type of solution significantly increases control over the technological process and allows for real-time response to changing operating conditions.

Depending on the process and technical requirements, we offer both invasive and non-invasive flow measurement methods.

Thanks to heat measurements (the energy contained in the flowing steam), it is possible to effectively manage energy consumption, improve process efficiency and quality, and achieve real business gains.

In the context of heat measurement, this also plays an important role in terms of environmental protection and responsible resource management.

🎥 We invite you to watch a short video of this implementation, where we show how the installed system works in practice: