Aktualności

We started the entire project by developing a technical concept, within which we prepared several solution options. Our goal was to best meet the expectations of the end user and the limitations resulting from the technology and infrastructure of the plant.

In the next stage, we developed design guidelines for the other companies involved in the project, responsible for the modernisation of the 6kV power supply field and the master control system. On this basis, we prepared a complete electrical design, taking into account the connections to the power supply and control infrastructure and the location of the soft starter, with careful consideration of the load-bearing capacity of the ceiling.

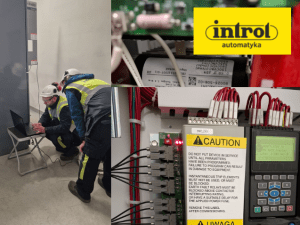

As part of the preparations for installation, we identified unmarked 6kV cables running along routes in the cable room, which allowed for safe and precise installation work. We then delivered the device to its final destination in the switchgear room using a telescopic loader with a reach of 17 metres.

The device installation included drilling holes in the ceiling with a concrete drill, mounting the soft starter and installing additional cable ladders in the cable room. As part of the electrical work, we cut and removed the previously identified 6kV cable, which was then connected to the soft starter. The second section of the cable was extended using a cable sleeve and also connected to the device.

Finally, we carried out a series of commissioning tests – from internal soft start tests, including thyristor gating checks using an oscilloscope, through tests with the power supply and master system, to trial fan starts. The tests were carried out with different current limit settings in order to select the most optimal start-up time and method.

After all stages were completed successfully, the project was handed over for operation.