Innovative Process Control Systems, HVAC, Gas Detection, and Production Automation for Industrial Efficiency

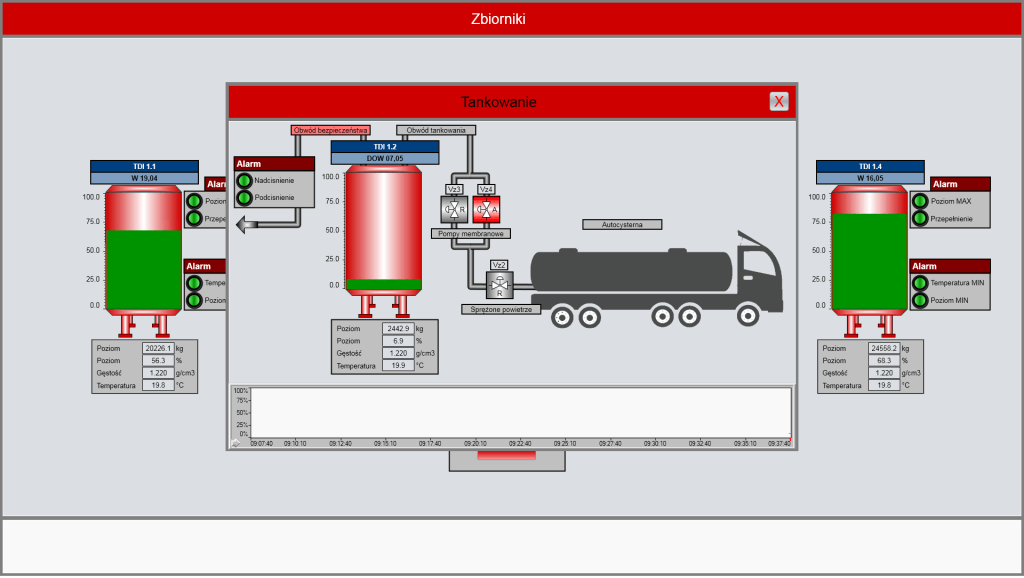

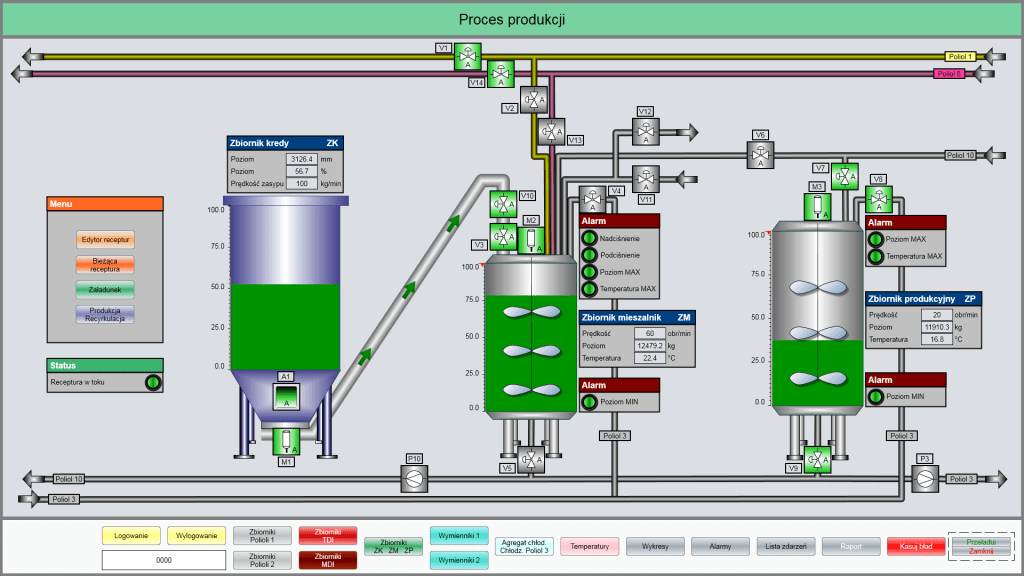

Process control: effective monitoring systems

One of the key solutions implemented for the food and processing industry is monitoring of utility consumption, using a SCADA system. The structure of the utility consumption monitoring system is flexible and allows for expansion at any time. Typically, we use the existing network at the site to make optimal use of the available infrastructure. For any security requirements, we set up a dedicated network. We use a variety of SCADA software platforms, allowing us to tailor the right system and integrate with existing equipment on site. This ensures easy integration with existing systems on site.

Media monitoring system:.

- Phased system construction,

- multi-level nature (different production lines, departments, plants),

- precise determination of production costs,

- integration into existing systems, e.g. SAP,

- cost oversight,

- visualisation,

- registration of data from the system,

- reporting according to an agreed algorithm.

Compressed air supply systems: efficient solutions for your business

Consistent and reliable access to compressed air is a key element in the food production process. Compressed air must be free of all contaminants such as moisture, oil, dust and bacteria to ensure high quality standards are maintained. Regardless of the type of food production, be it beverages, confectionery, dairy or cured meats, the need to have access to clean compressed air is essential to maintain optimal production conditions.

In the food industry, coupled air is used, among other things, in processes such as:.

- the pre-blowing process for plants transporting liquid ingredients,

- process mixing liquids in tankers for the transport of milk,

- the process of creating overpressure in tanks of intermediate product with higher density,

- opening and closing of pneumatic valves,

- the process of drying washed vegetables and fruits, just before packaging.

Innovative HVAC systems: ventilation and air conditioning for comfort and efficiency

We carry out cleanroom, production and auxiliary room projects in new and existing facilities. Our services include comprehensive solutions from ventilation, air-conditioning and process installations for both aseptic and non-sterile production areas. We operate according to the individual needs and requirements of our customers.

Our engineering staff, with 15 years of experience in an EU GMP (Good Manufacturing Practice) environment, provides full technical support at every stage of the investment, from conception through to implementation and commissioning and service supervision. In addition, we offer support in the qualification process of the systems and installations described.

The HVAC installation provides:.

- inlet of clean air with parameters, environmental, suitable for the processes and cleanliness zones carried out ( Temperature T, Pressure P , humidity H, number of particles ),

- continuous exchange and maintenance of adequate air quality including room cleanliness class during sterile or non-sterile production operations,

- protection against the accumulation of excessive moisture and its condensation, the occurrence of which can contribute to a reduction in the quality of the room environment and have a negative impact on the product,

- safety and adequate thermal comfort of users in rooms with particularly high dust levels such as free-flowing materials, greenhouses, sorting rooms etc,

- removal from premises of potential contaminants of high explosive, toxicological risk,

- lower overall operating costs of the premises, in relation to heating, ventilation as well as air conditioning working alone,

- the possibility of local temperature control – for example: sample storage rooms for stability testing.

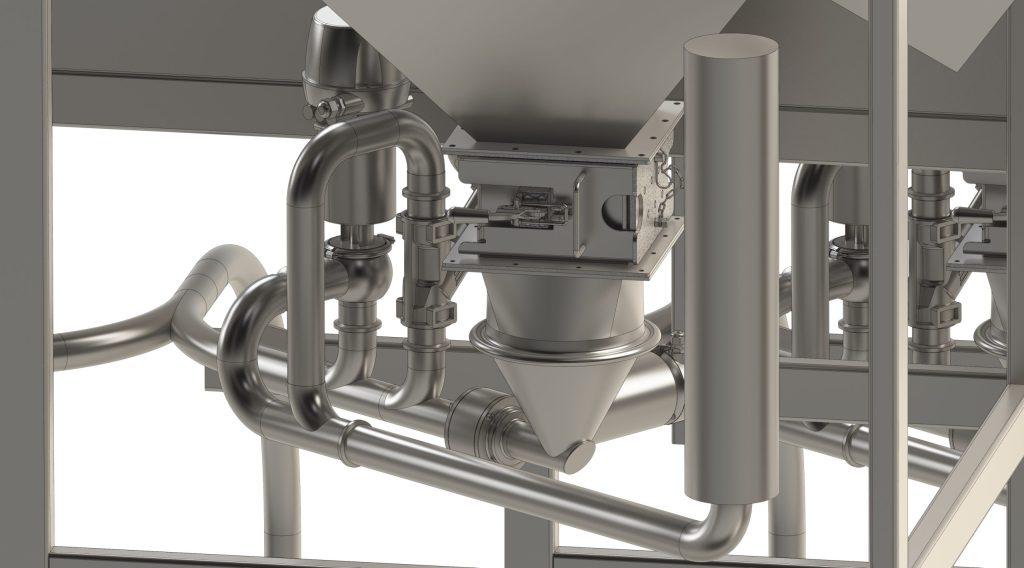

Efficient vacuum transport system for efficient handling of bulk materials

Our solution includes the supply and installation of components of a vacuum transport system, ensuring efficient and dust-free handling of bulk components such as powders, granules, etc. Vacuum transport of bulk materials is carried out in a closed system, which eliminates the risk of foreign materials contaminating the product. This is particularly important in the food industry, where maintaining product purity is a priority. It is worth noting that our solution prevents spillage of materials and contamination of the production environment, which contributes to maintaining high hygienic standards.

Benefits of vacuum transport:.

- reduction of waste and product contamination,

- small footprint,

- minimal handling,

- dust-free working environment,

- flexibility of production.

SmArtGas 4: stationary gas detection sensor for monitoring concentrations of hazardous substances

SmArtGas 4 is a stationary detector providing monitoring of non-hazardous gas concentrations through continuous diffusion measurement..

It is designed for operation in explosive atmospheres and in hard industrial conditions where a change in environmental conditions can occur over a wide range (high temperatures, corrosive gases or vapours, moisture and dust).

The sensor can be equipped with a modern measuring head (“FL, FH”) with very good measuring properties. Thanks to this, the sensor cooperating with the pellistor sensor has achieved more than twice the response times (T90)* thus becoming one of the fastest devices.

The detector of the SmArtGas 4 series can be equipped with additional protection of the measuring elements against environmental influences (water, dust) by means of a Teflon membrane. This has made it possible to achieve an IP level of IP67.

Additional features include:.

- extended interface connection,

- increased voltage supply (up to 50 V),

- introduced drift reduction mechanisms,

- long-term use of catalytic sensors,

- the use of a membrane ensuring,

- waterproofing of the detector,

- optional sensor heating.

Process refractometer: precise measurement under industrial conditions

Thanks to its use of refractive index measurement in solution, the instrument is ideal for application of BRIX – sugar concentration in solution. Thanks to its ability to develop its own measurement curves, it is also used to measure the concentrations of other substances in homogeneous solutions.

Process refractometers are used primarily in the food industry, in the sugar industry, in juice production, but also in the pharmaceutical industry, the chemical industry and wherever continuous measurement of solution concentration is required.

Additional features include:.

- the device and measuring chambers comply with sanitary standards and have EHEDG certification (the device is made entirely of 316 stainless steel and the process part of 316L, the optical elements of the sensor are behind sapphire glass which is resistant to mechanical damage),

- In applications where deposits can occur on the prism, measuring chambers are available with optional washing of the optical glass with steam or high-pressure water (the devices freeze the measurement for the duration of the prism washing so as not to disrupt the process),

- The refractometer has two analogue outputs and a digital output with MODBUS TCP protocol, as well as a webserver for measurement control from a web browser.

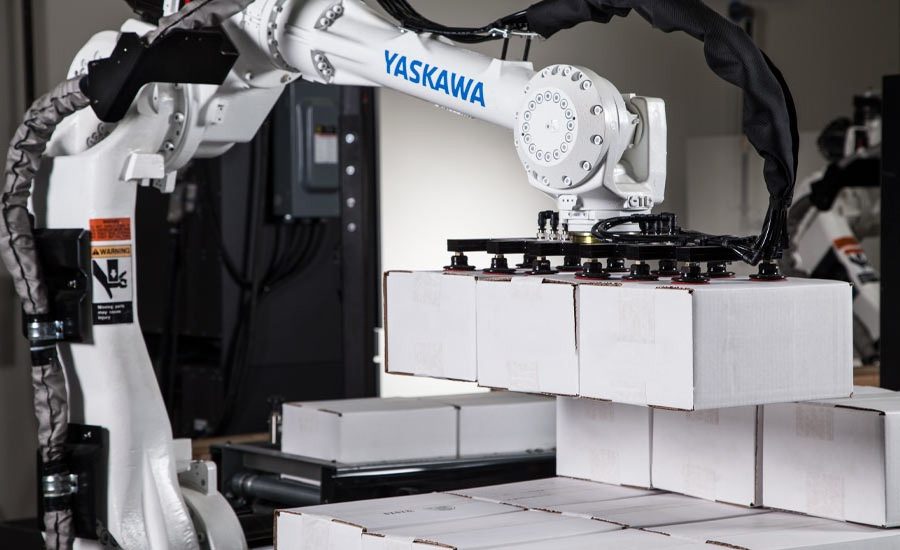

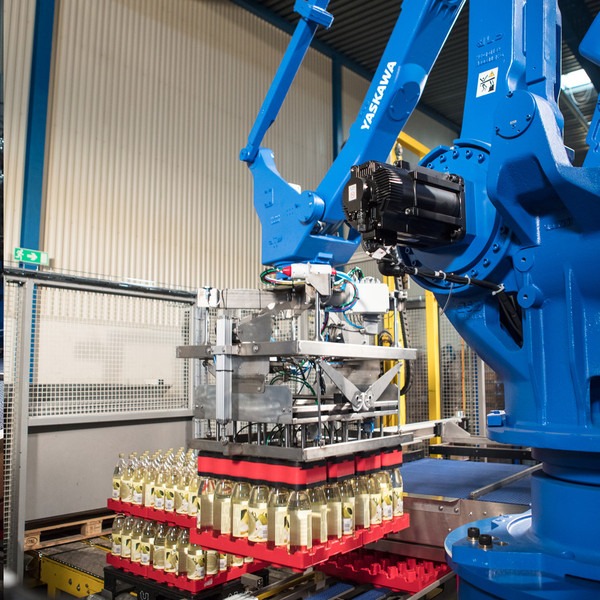

Industrial robots and cobots: automating production processes

Characteristic of the food industry is the concern for the highest standards of cleanliness, which forces manufacturers to use robots with an appropriate design, which consists of various types of housings, covers, covers and seals for moving parts. This is primarily to prevent the effects of water, cleaning agents, acids, as well as the manufactured product.

On the other hand, it is worth mentioning that the design of such a robot must also ensure that the highest level of hygiene is maintained in such a way that the consumables used in it, such as lubricants and oils, are neutral to the manufactured product.

Applications where robots are most commonly used:

- sorting,

- packaging,

- palletising,

- depalletisation