Professional Flow Measurements, Frequency Inventers and SCADA Systems for Efficient Process Control

Flow measurements in open channels

We carry out flow measurements on open channel using hose of all types, in accordance with Polish and European standards:

- ISA orifice plate with three-disc measurement

- ISA orifice with D and D/2 metering

- segmental orifice

- ISA nozzle.

- Venturi nozzle.

- classic Venturi tube

We also implement:.

- measurement of flow in an non-normalised duct using a VEGA radar transducer and Manning’s formula,

- measurement of the flow in an unnormalised channel using a VEGA transducer and an appropriately constructed edge – steering wheel, matched to the parameters and flow velocity.

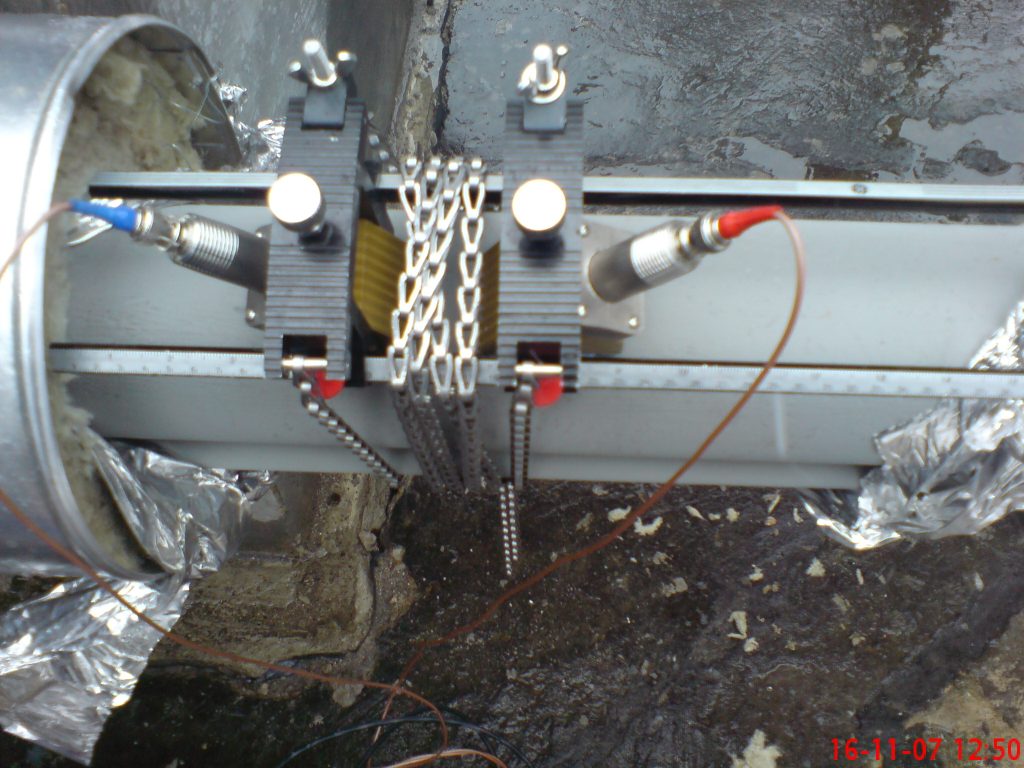

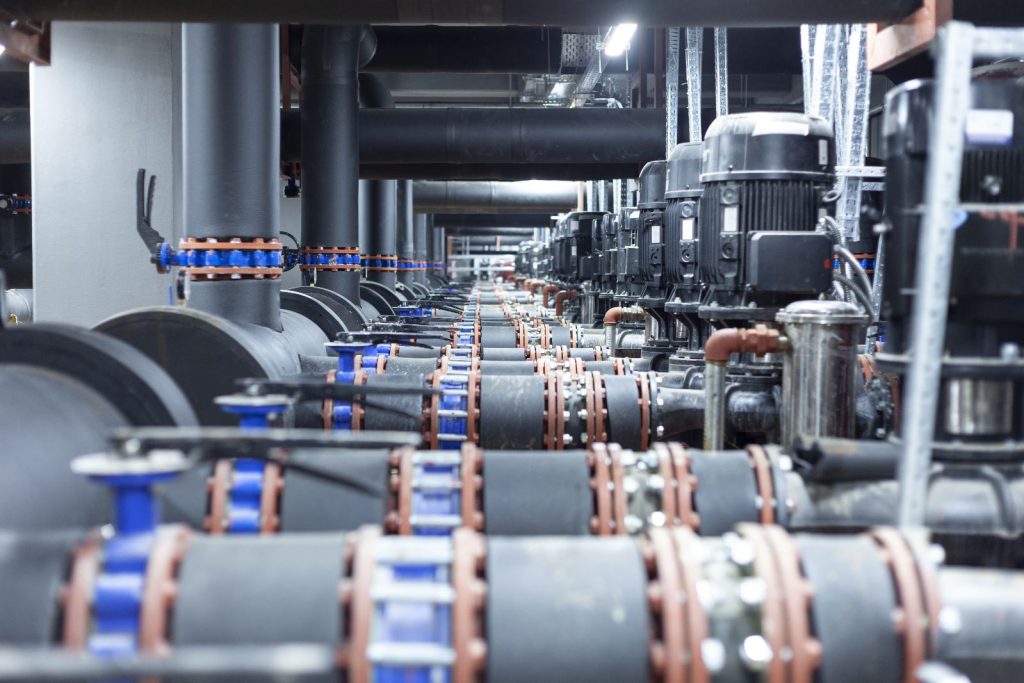

Non-invasive measurements on buses

For non-invasive flow measurement on buses, ultrasound measurements are used. Ultrasonic flowmeters (e.g. Flexim) enable highly accurate measurement (less than 1% error) with the possibility of installation on buses located in dense urban and industrial infrastructure. Solutions of this type work in conjunction with external communication systems, providing the opportunity for online monitoring of metering data.

Benefits:.

- no pressure drops during measurements,

- degree of protection of probes IP67 or IP68,.

- manufacture of portable version and stationary version,.

- diameter range from 7mm – 6,500mm.

Other measurements

Thanks to the long-standing experience of Introl Automation in water and wastewater management, we guarantee the optimal selection of measuring devices to meet the requirements of the application. We participate in the implementation of tasks from the concept process through design to assembly and commissioning.

We supply and implement:.

- Projects measuring systems,

- measurements of levels, temperature, pressure,

- gas flow measurements,

- physical and chemical measurements,

- weighing systems,

- detection systems,

- process control systems,

- 24h surveillance.

Rockwell Automation LVD low voltage drives

Low Voltage Drives (LVD), i.e. frequency inverters and soft-start systems, include devices and solutions that are designed to offer efficient machine and equipment operation, machine safety, low operating costs and high product reliability. The low voltage drive systems on offer are based on key components from the Allen-Bradley brand. They are designed to operate in the most demanding environmental conditions. The LVD range includes inverters in the PowerFlex AC and PowerFlex DC architecture classes. The use of PowerFlex converters provides cost-effective solutions for stand-alone control applications for single machines and integrated systems. Increased motor control efficiency and improved motor performance through the use of motor control means higher overall production efficiency.

- safety features protecting personnel and property while reducing downtime,

- perfect integration with the Logix environment streamlining configuration and software,

- protection against unscheduled stops thanks to advanced diagnostics , and notification of unstable operating parameters,

- access to data in real time for decision-making, facilitating smooth production processes,

- reduction in maintenance and energy consumption of up to 60%,

- high reliability compared to other similar products on the market,

- highest efficiency in its class as confirmed by the international IEC 61800-9-2 standards for defining efficiency and energy efficiency for drive systems.

Yaskawa LVD low-voltage inverters

A group of low-voltage frequency inverters for special solutions in the control of hoisting motors (e.g. passenger cranes, goods lifts), moving escalators, screw feeders, sliders, conveyors. The knowledge and experience gained over decades in industrial automation, is confirmed by 22 million installed inverters worldwide. Their quality and special design predestine them for use in highly specialised applications. An example of a dedicated frequency converter model is the U1000, which is ideally suited to single-motor drive applications requiring low harmonic distortion and generator mode capability. It is also ideal for HVAC and many other applications. The high efficiency of the converters together with the near unity power factor ensures sinusoidal input current, and enables reduced losses in generators, transformers and power cables.

- the best driving comfort is provided by special control algorithms and dedicated elevator control functions,

- quick, simplified configuration with automatic tuning at rest without the need to remove the cables, the default settings are selected to suit the needs of most installations,

- brake monitoring as part of the protection against unintended cab movement, reducing implementation costs,

- operation without motor contactors reduces audible noise and implementation and maintenance costs, without compromising safety conditions,

- innovative MATRIX low-voltage technology with direct AC-to-AC energy conversion ensuring energy return to the grid even for very low drive powers (a few kW),

- low levels of higher harmonics without the need for additional filters.

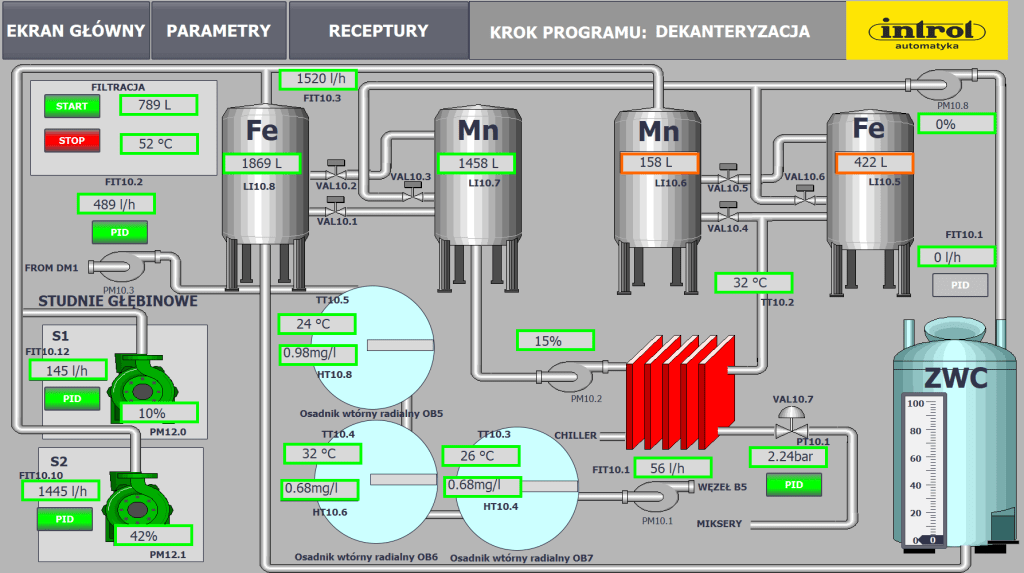

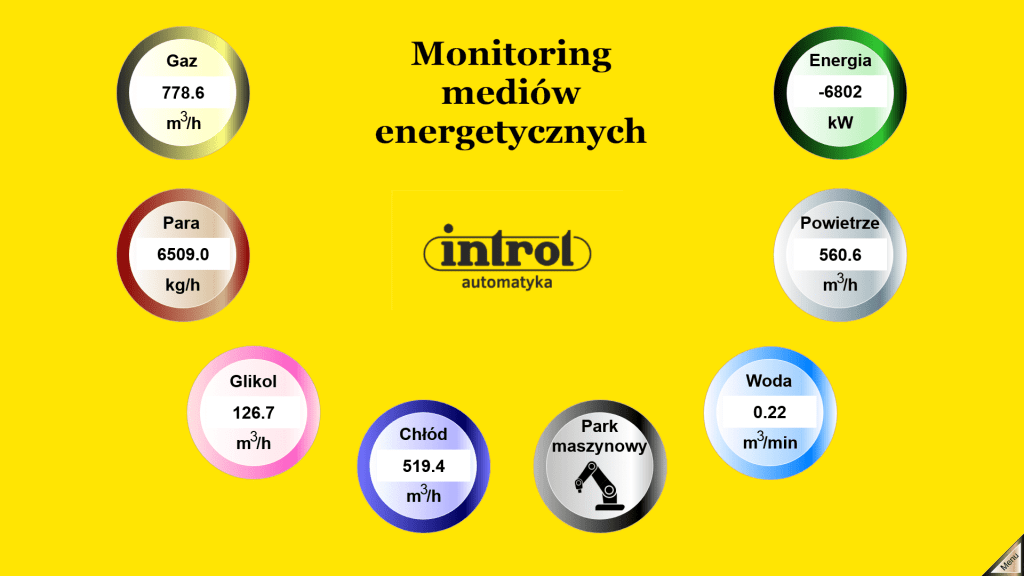

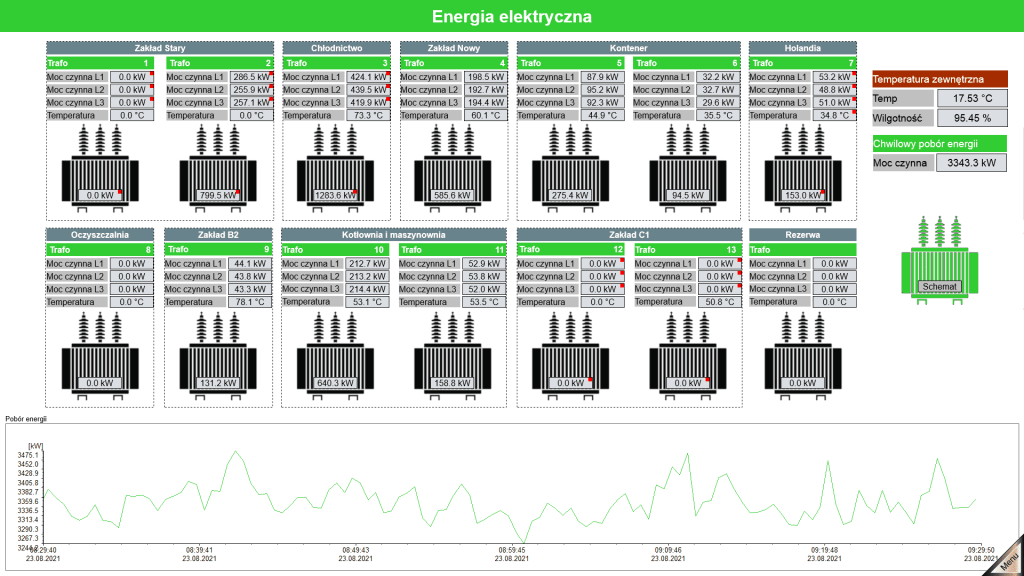

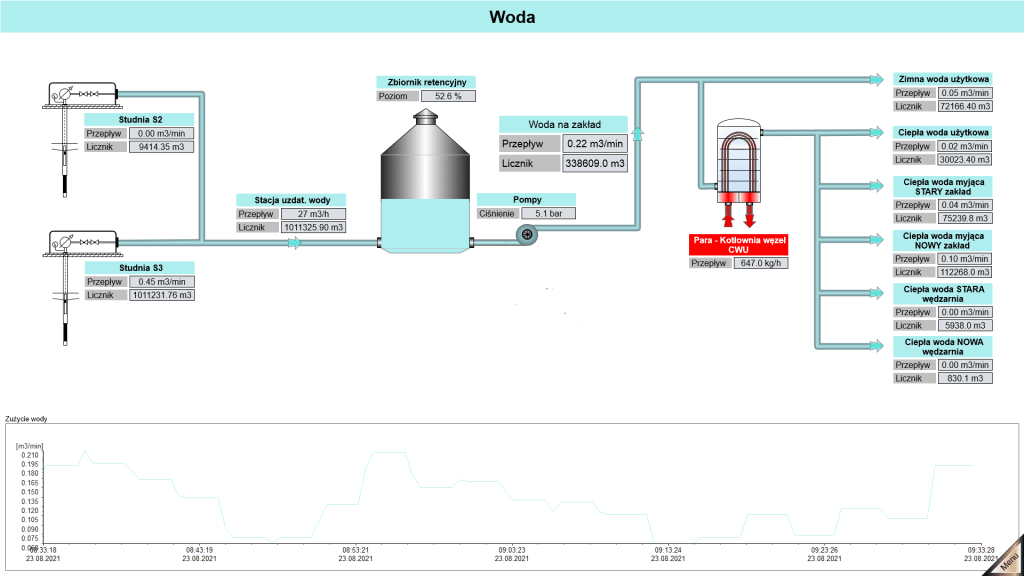

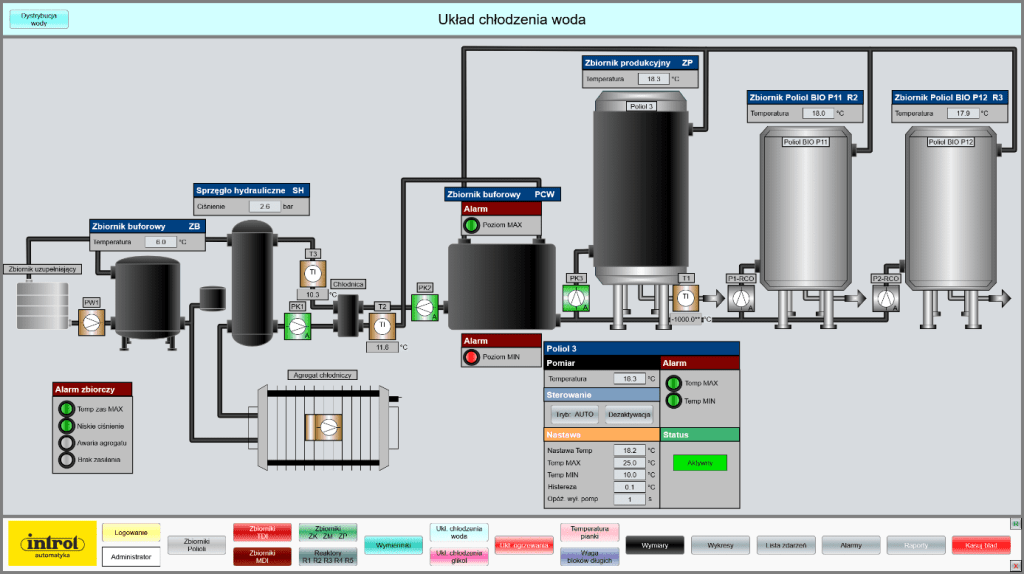

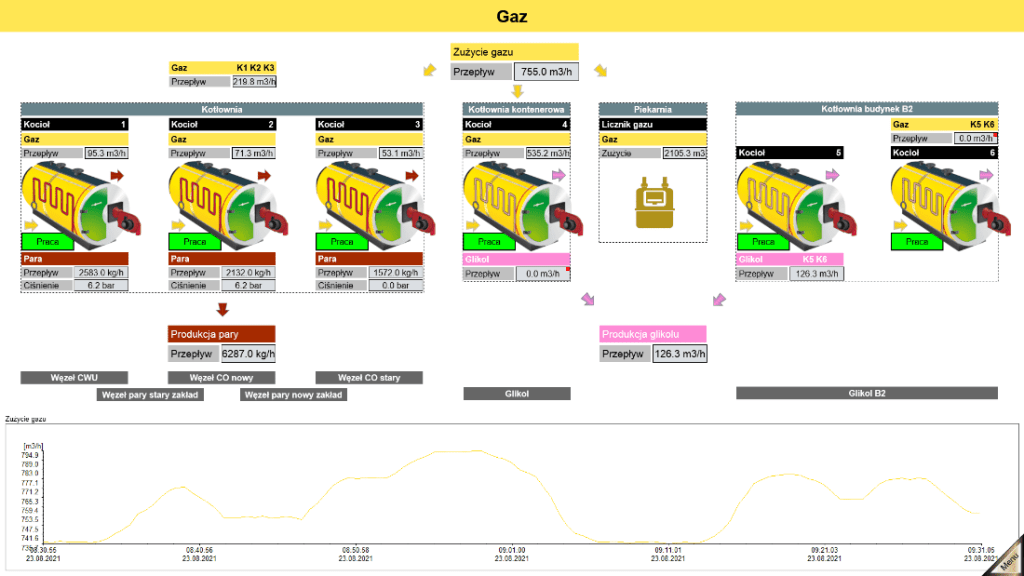

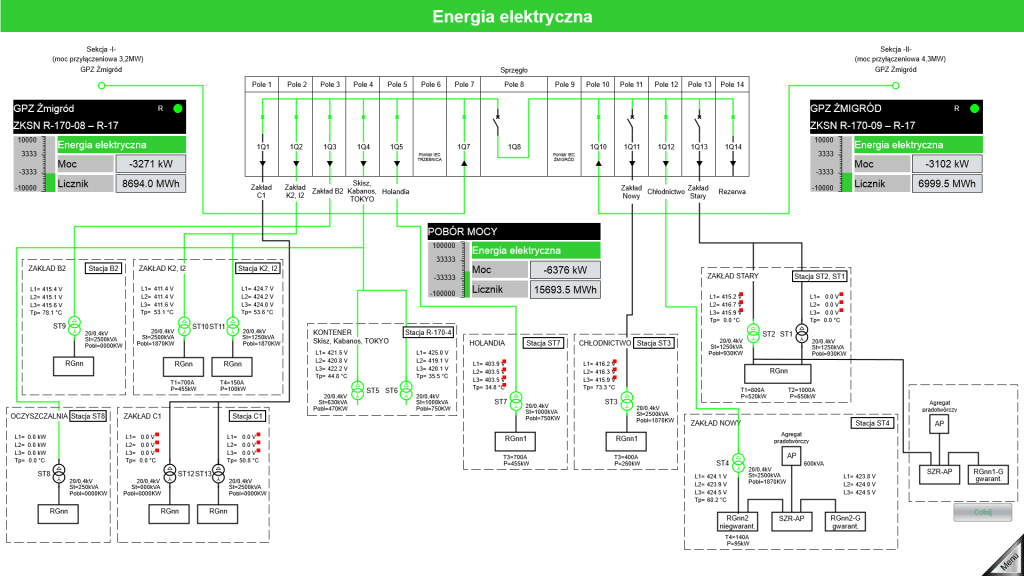

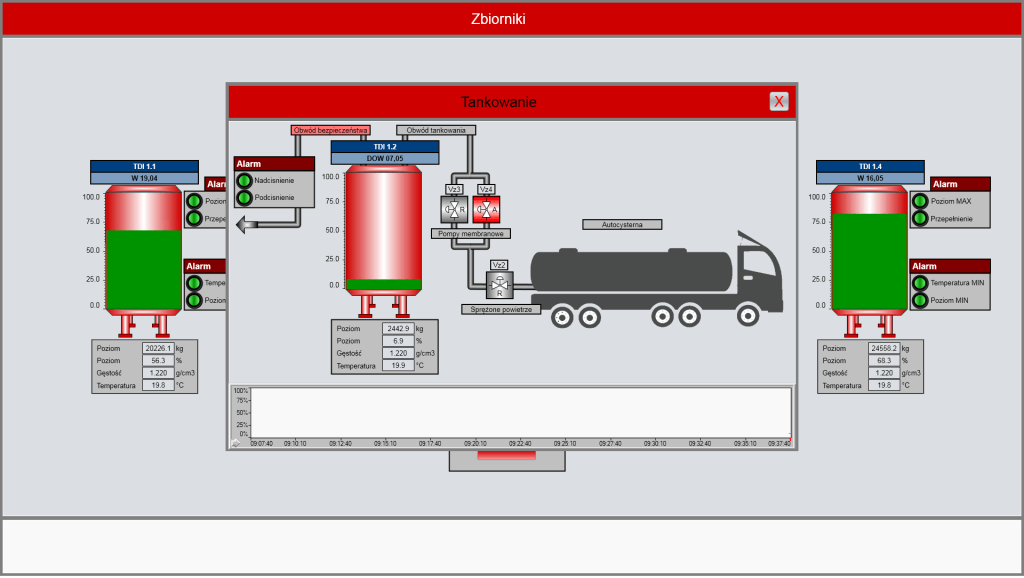

Process control and SCADA systems

We have decades of experience in measurement of various types of utilities. We comprehensively implement media consumption monitoring systems. In an era of volatile prices for both gas and electricity, the implementation of a system that allows for control, and, above all, analysis of utility consumption in production plants makes it possible to find savings in fixed costs. The systems we implement allow monitoring of electricity, natural gas, compressed air, steam, heat or cooling. Each application is created from scratch and tailored to the specific facility and customer expectations. Our engineers together with representatives of the Investor define the scope of the project, define milestones and jointly define the system concept. At each stage of the project important issues are agreed upon with the Investor.

The structure of the utility consumption monitoring system is distributed and allows it to be extended at any time. We typically use the network available at a particular site to make the best use of the available infrastructure. If there are any safety requirements, we create a separate network.

We use all available SCADA software platforms. Selecting the right system enables us to take advantage of existing equipment on site. This also affects ease of integration with existing on-site systems.

Media monitoring system:.

- phased construction of the system,

- multi-level nature (different production lines, departments, plants),

- precise determination of production costs,

- integration into existing systems, e.g. SAP

- cost control

- visualisation,

- recording of data from the system,

- reporting according to an established algorithm.