Frequency Inverters and Control Systems for Industrial Automation and Energy Sector

MVD Medium Voltage Drives

For more than 15 years, the MVD (Medium Voltage Drives) division has been a leader in the implementation of comprehensive solutions in the field of frequency inverters and soft-start systems for Polish industry. Our experience covers a wide range of advanced projects in which we have successfully applied medium voltage frequency inverters. Over the years, we have completed numerous applications using medium voltage inverters and soft starters, continuously improving the quality of our services.

We are proud to be the first in Poland to use medium voltage converters for speed control of belt conveyors, confirming our innovative and advanced approach to technology. In addition, our track record also includes the use of 6kV drive systems in a variety of applications such as exhaust fans, air fans and feed and mains water pumps.

If you are looking for experts in frequency inverters and soft-start systems, the MVD Drives Division is the ideal partner to provide a comprehensive service and state-of-the-art solutions tailored to your needs.

- As one of two companies in Poland, we are certified in the Power programme by Rockwell Automation. We have the possibility to carry out independent commissioning and servicing of equipment such as medium-voltage frequency converters (medium-voltage inverters) and medium-voltage soft starters during their warranty period, which until now was only carried out by the Manufacturer,

- Power certification in the Recognized System Integrator partner programme of Rockwell Automation is an extension of our existing cooperation in the field of control system integration, in which we have already been certified by the Control programme for many years,

- Our Power certification would not have been possible without the trust of “Polish industry” and our numerous implementations in the field of medium voltage drive systems in projects (belt conveyors, exhaust fans, pumps). The trust placed in us by Rockwell Automation allows for even better cooperation and continuous development by improving our qualifications,

- It is with undisguised satisfaction that we are able to appreciate the fact that our contractors can appreciate our commitment to their projects, which offers even better opportunities for future cooperation and for winning numerous contracts in the constantly growing medium-voltage drive industry.

Rockwell Automation LVD low voltage drives

LVD (Low Voltage Drives) such asfrequency inverters and soft-start systems are key components in ensuring efficient operation of machinery and equipment, while raising safety standards, reducing operating costs and guaranteeing high reliability. The solutions we offer are based on renowned components from the Allen-Bradley brand, adapted to operate in the most demanding environmental conditions.

Our low-voltage drive systems include PowerFlex AC and DC inverters, guaranteeing a wide range of applications. The use of PowerFlex inverters provides cost-effective solutions, both for individual machines and integrated control systems. Their use results in higher motor control efficiency and superior performance, which translates into increased efficiency throughout the production process.

- safety features protecting personnel and property while reducing downtime,

- perfect integration with the Logix environment streamlining configuration and software,

- protection against unscheduled stops thanks to advanced diagnostics , and notification of unstable operating parameters,

- access to data in real time for decision-making, facilitating smooth production processes,

- reducing maintenance and energy consumption by up to 60%,

- high reliability compared to other similar products on the market,

- highest efficiency in its class as confirmed by the international IEC 61800-9-2 standards for the definition of efficiency and energy efficiency for drive systems.

Yaskawa LVD low-voltage frequency inverters

Our range includes a group of low-voltage frequency converters specifically designed for advanced applications in the control of lifting motors, such as passenger and freight cranes, escalators, screw feeders, winders and conveyors. Thanks to our extensive knowledge and many years of experience in the field of industrial automation, our drives are trusted by customers all over the world. More than 22 million have already been installed.

Our products are distinguished by their high quality and specially designed construction, making them ideal for highly specialised applications. One dedicated inverter model is the U1000 by Yaskawa, which is ideal for single-motor drive applications with low harmonic distortion and generator mode capability. In addition, it also works well in HVAC applications and many others.

Our inverters are characterised by high efficiency and a power factor close to unity, resulting in sinusoidal input current and reduced losses in generators, transformers and power cables. As a result, our solutions optimise energy efficiency and minimise operating costs.

- the best driving comfort is provided by special control algorithms and dedicated elevator control functions,

- fast, simplified configuration with automatic tuning at rest without the need to remove the cables, default settings are selected to suit the needs of most installations,

- brake monitoring as part of the protection against unintended cab movement, reducing implementation costs,

- operation without motor contactors reduces audible noise and implementation and maintenance costs, without compromising safety conditions,

- innovative MATRIX low-voltage technology with direct AC-to-AC energy conversion ensuring energy return to the grid even for very low drive powers (a few kW),

- low levels of higher harmonics without the need for additional filters.

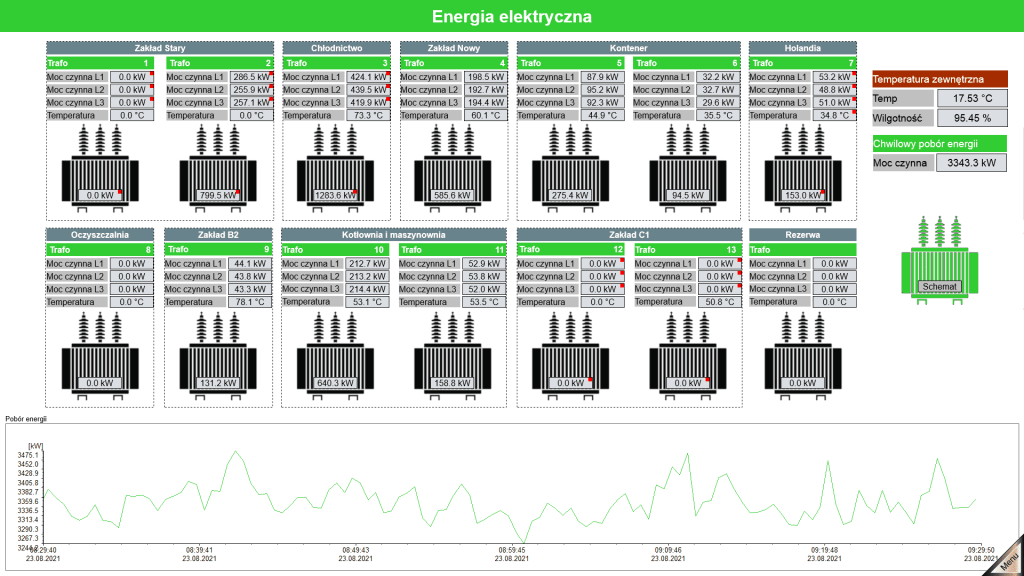

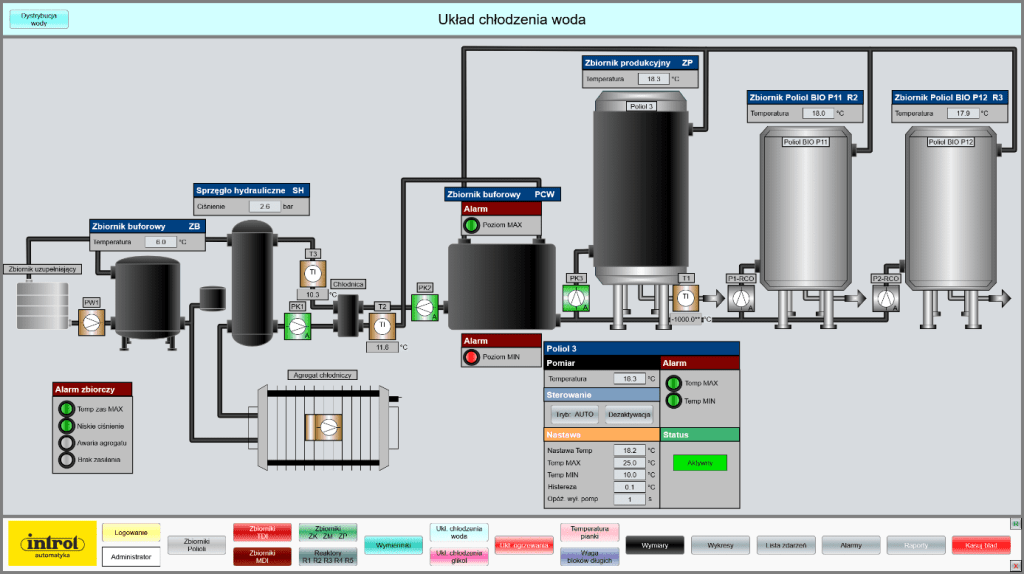

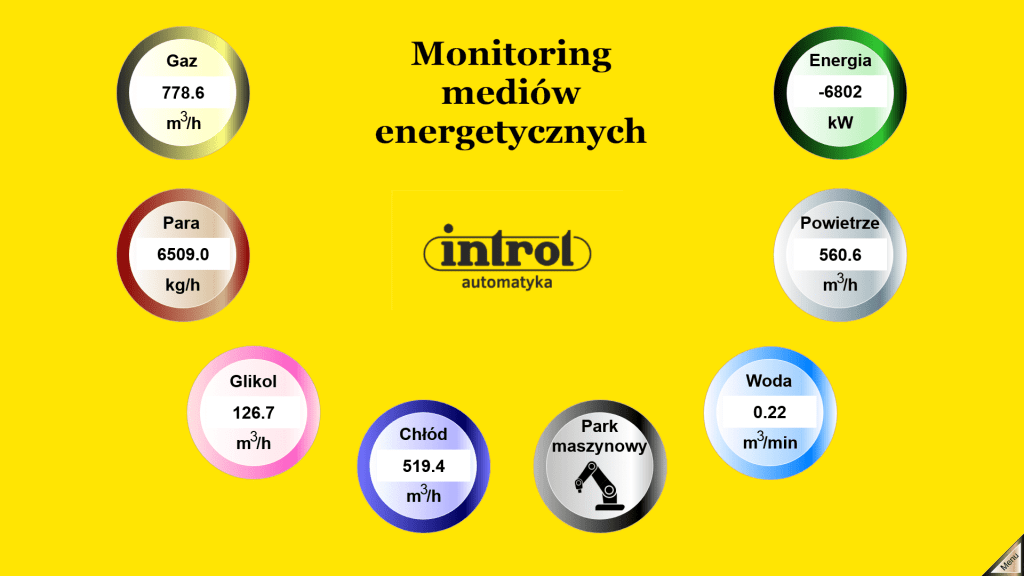

Process control and SCADA systems

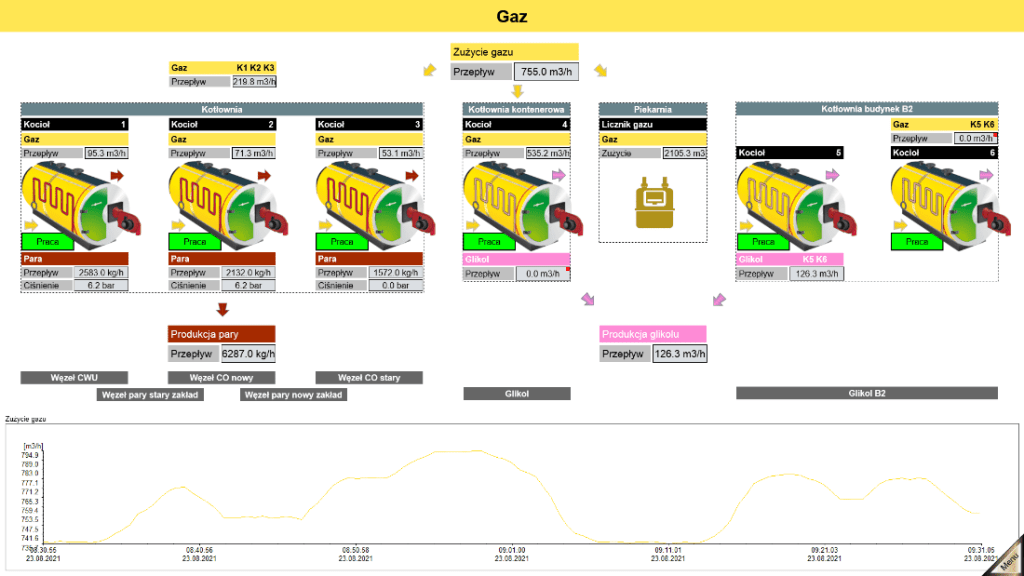

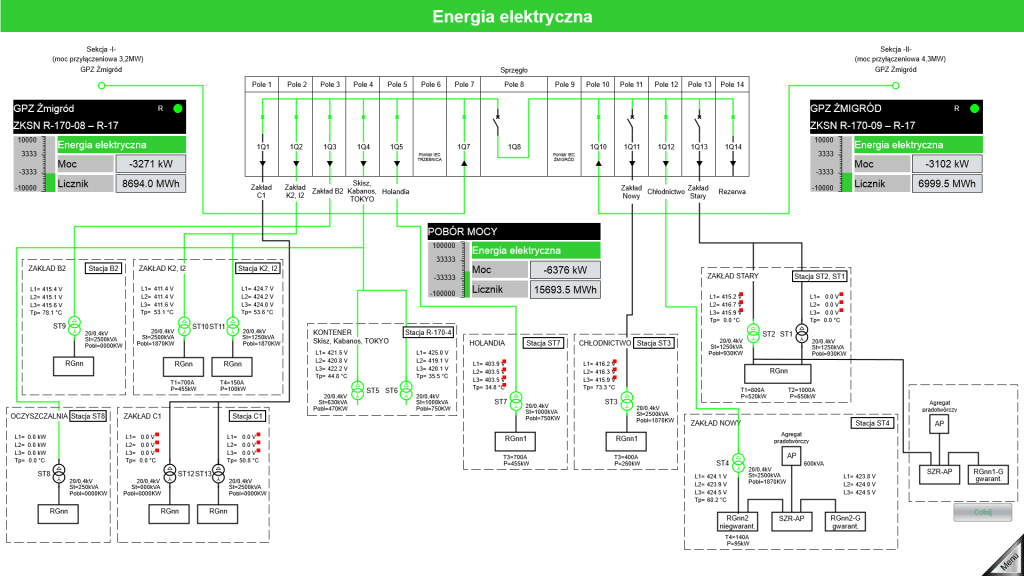

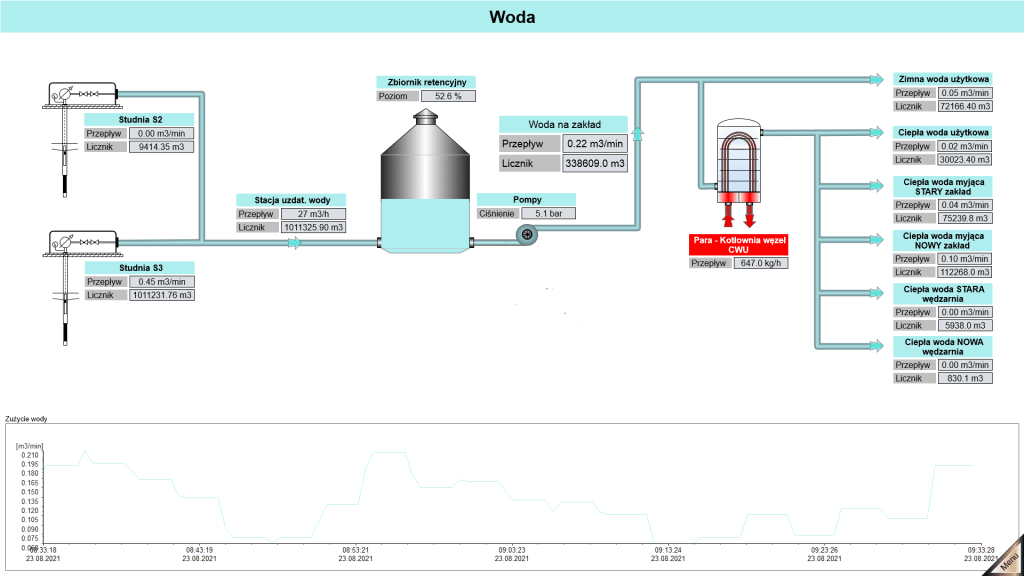

We have many years of experience in the field of measuring a wide variety of utilities. Our company specialises in the comprehensive implementation of media consumption monitoring systems. In the face of constant changes in the prices of electricity and gas, it is becoming important to implement a system that enables the control and detailed analysis of utility consumption in a production facility. This makes it possible to find ways to reduce fixed costs.

Our solutions allow us to monitor the consumption of various utilities such as electricity, natural gas, compressed air, steam, heat or cooling. Each application is designed from the ground up and tailored to the individual needs and expectations of the customer.

The structure of our media monitoring systems is flexible and allows for easy expansion at any time. We typically make use of the existing network infrastructure at the site to optimise costs and make efficient use of existing resources.

We use a variety of software platforms SCADA, which enables the use of existing equipment and integration with existing systems on site. Additionally, for security requirements, we create dedicated, separate networks. This makes our solutions versatile, easy to integrate and tailored to specific customer needs

Media monitoring system:.

- phased construction of the system,

- multi-level nature (different production lines, departments, plants),

- precise determination of production costs,

- integration into existing systems, e.g. SAP,

- cost monitoring,

- visualisation,

- recording of data from the system,

- reporting according to an established algorithm.

Measurement of thermal energy

Power plants and Combined Heat and Power plants are key industrial institutions, generating significant amounts of electricity and heat. In this context, precise heat energy measurement plays a key role in the effective management and billing of consumption in such facilities.

Since our early days, one of our main areas of focus has been energy metering systems, including energy measurement of water, water-glycol mixtures and steam. Our energy and steam mass measurement solutions are fully complete and use all market-approved measurement methods.

Thanks to our experience and expertise, we are able to provide comprehensive measurement systems that meet the highest industry standards and requirements. Our solutions ensure not only precise measurement, but also effective control of thermal energy consumption, resulting in optimal resource management and minimised operating costs.

We implement:.

- billing thermal energy measurements of water with MID (Measuring Instrument Directive) approval for the full range of diameters,

- billing cold energy measurements for the full range of diameters,

- energy and mass measurements of steam in the full range of its parameters as well as pipeline diameters.

For steam flow measurement we install measuring systems:.

- based on back pressure (nozzles, orifices, cones) and differential pressure measurement with full compensation from pressure and temperature,

- based on vortex meters with full compensation from pressure and temperature,

- ultrasonic measuring systems.

Control and measurement systems in the power industry

In the energy industry, in addition to standard heat energy measurements, we specialise in complex measurement systems including dgas detection, level and temperature measurements, physical and chemical analysis of liquids and weight measurements. Our team of engineers is specialised in the design and implementation of complete measurement systems, tailoring ACP equipment to the specific needs of each application.

The quality of our solutions is guaranteed by dedicated installation and service support, which we provide for up to 10 years. Long-term service care has become a standard that meets the expectations of our customers and assures them of the operational certainty and reliability of the installation.

We carry out:.

- stationary gas detection systems,

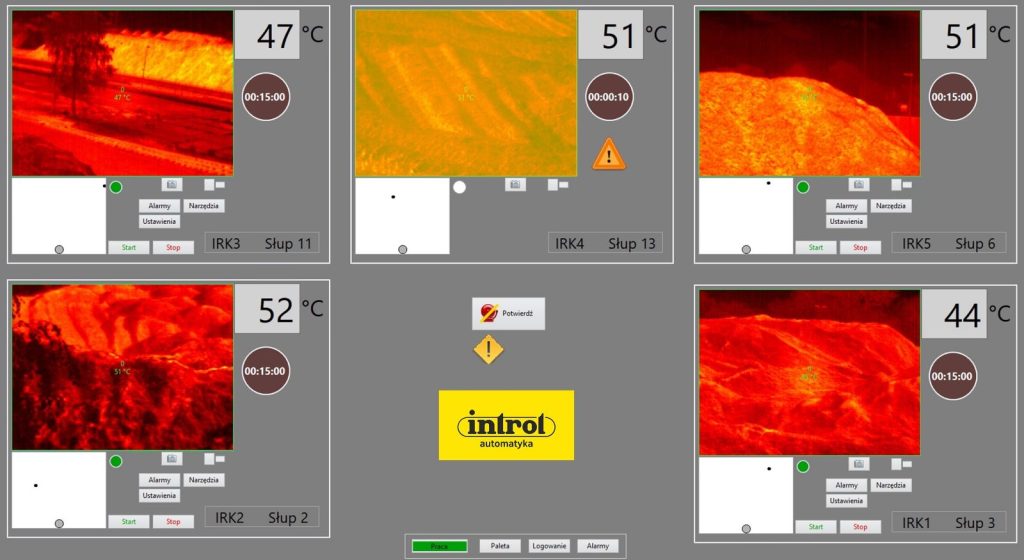

- temperature measurement, e.g.

- on conveyor belts using scanners,

- on biomass stockpiles using a thermal imaging camera,

- in biomass silos using measuring ropes,

- .measurement of the mass of transported material on a conveyor belt (coal, coal fines, gypsum),

- level measurement in coal bunkers.