Realizations

Supply and commissioning of 6 kV converters on one of the Power Plant units together with by-pass systems and spare parts

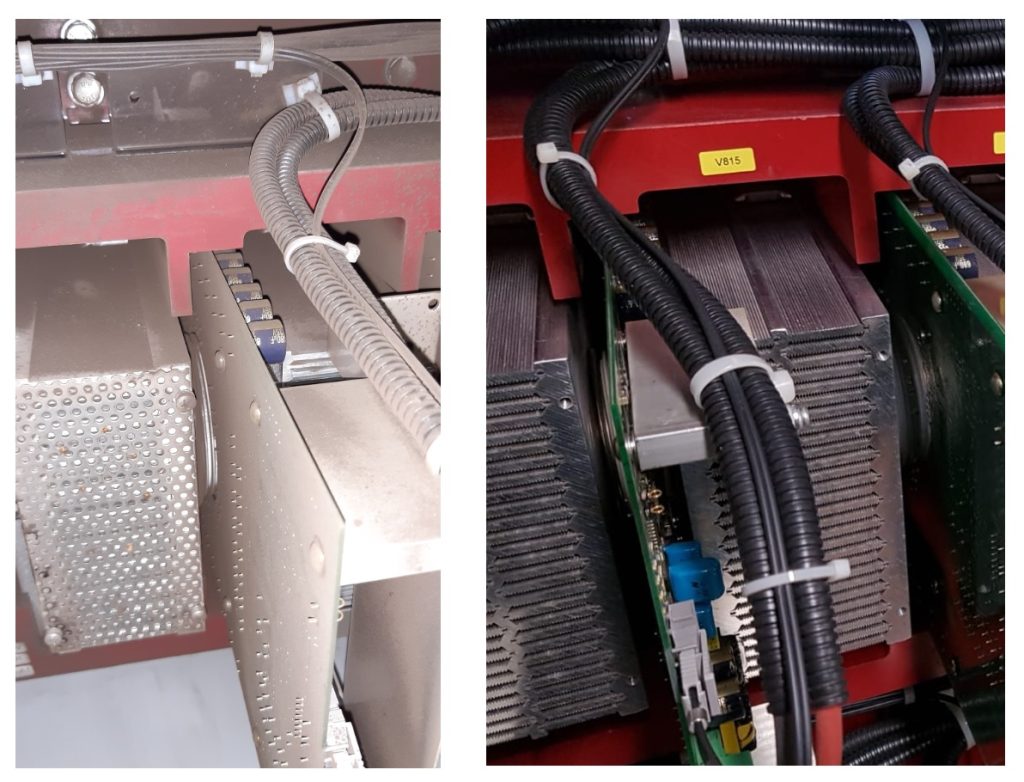

The task included the installation of PowerFlex 7000 medium voltage converters (current type) as part of the upgrading of the existing power supply flue gas fan motors and blast. The investment was carried out as part of the “Blocks 200+” programme for a coal-fired power plant located in eastern Poland.

Delivery and commissioning of PowerFlex 7000 93A / 6kV frequency converter

The project comprised the supply and commissioning of a PowerFlex 7000 93A / 6kV frequency converter together with support at the design stage for the converter for the frequency control system of the 6kV 740 kW pumping unit at the pumping station II st. Water Intake.

Commissioning of the PowerFlex 7000

The project included the commissioning of the PowerFlex 7000 medium voltage converter, manufactured by Rockwell Automation, and participation in customer trials at the pump test station of Termomeccanica Pompe S.p.A. in La Spezia, Italy.

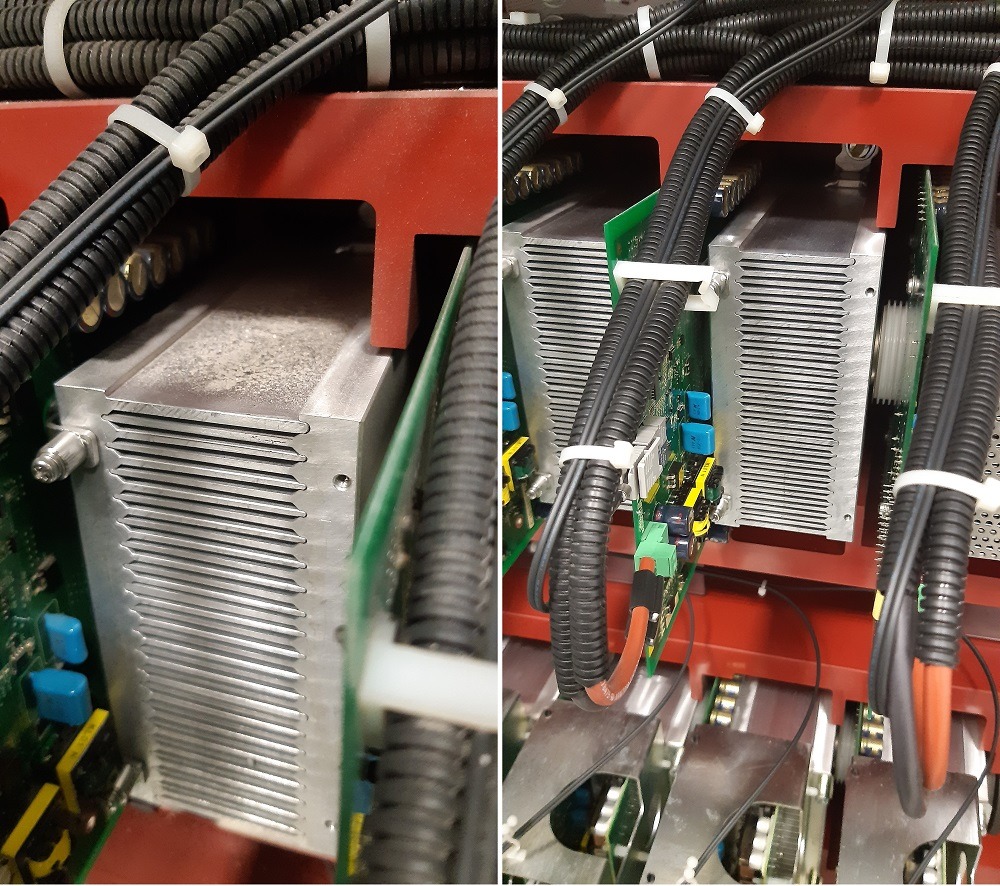

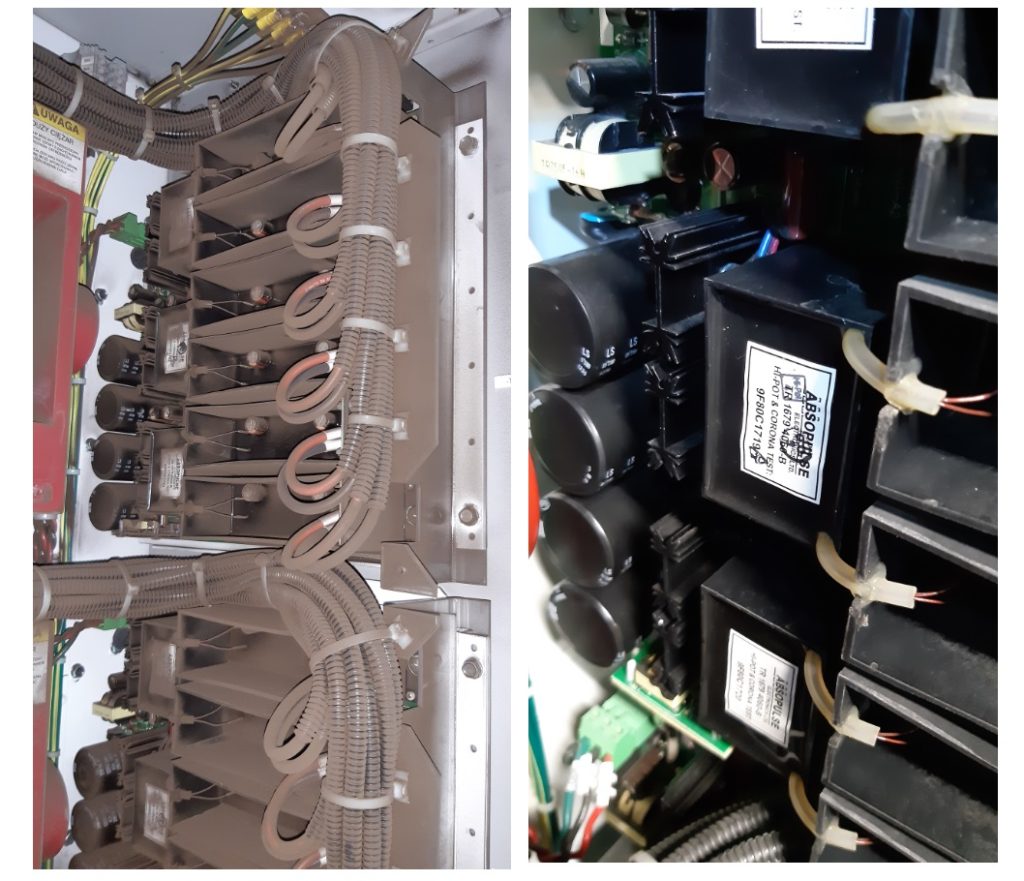

Preventive service of 6 kV frequency converters

Technical support of the customer in the current operation and system development work, contributed to the optimization of equipment operation and to the correct operation of technological systems.

Overview of two 6kV frequency converters, PowerFlex 7000

The converters operated in the flue gas fan plant of a coal-fired thermal power plant with installed electrical capacity of more than 240 MW and reachable thermal capacity of more than 800 MW.

Periodic inspection of fourteen converters

The review covered inverters of 6kV frequency type PowerFlex 7000 at a power plant for lignite with a total installed capacity of over 2,000 MW.

Replacement of 6kV inverter

Execution of replacement of 6kV inverter on a turnkey basis for the installation of a flue gas desulphurisation coal-fired combined heat and power plant with installed electrical capacity of over 240 MW and reachable thermal capacity of over 800 MW.

Modernisation of the flue gas fan control system

Modernization of fume fan control system at block 1 in the field of supply and installation of 6kV frequency converters at lignite power plants with total installed capacity of more than 2,000 MW.

Upgrading network water pumps

Modernization of 2 network water pumps with power of 1MW, 6kV together with by-pass systems at cogeneration plant coal with installed electrical capacity of over 240 MW and available thermal capacity of over 800 MW.

Supply and commissioning of medium-voltage frequency converters

Delivery and start-up frequency converters medium voltage PowerFlex 7000 air and exhaust fans and supply water pumps for the Investment “Construction of gas boilers together with auxiliary economies and construction of a steam turbine unit together with auxiliary economies“.

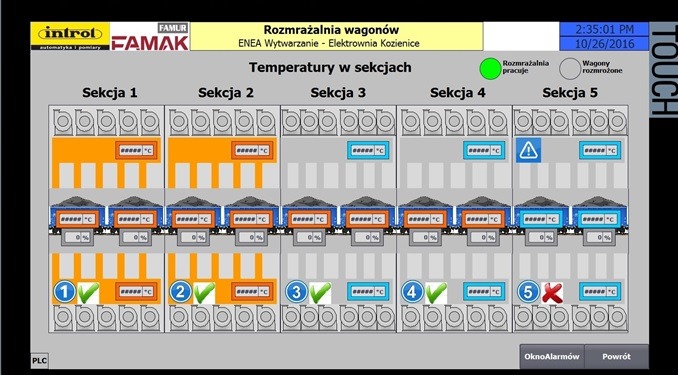

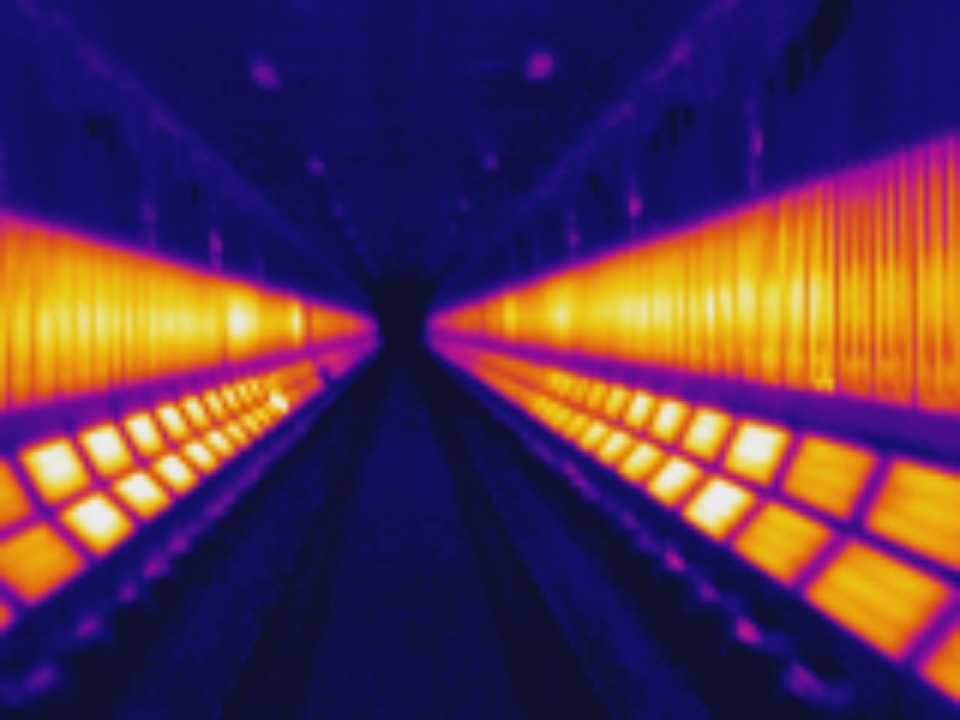

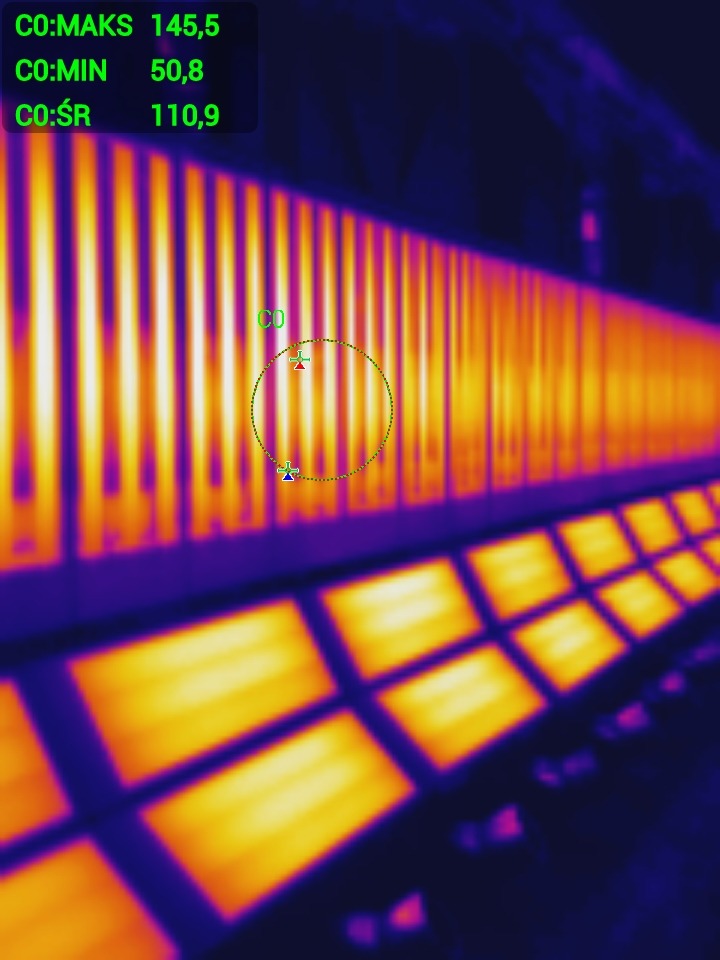

Coal wagon de-icing plant

The purpose of the coal wagon thawing room is to allow coal to be thawed from the wagon on the coal wagon thawing room. We achieve this by heating the walls of the wagon, which causes the coal layer to thaw from them. At the same time, we pay great attention to the temperature of the wheels, bearings and axles, which for safety reasons must not be heated to too high a temperature.