Comprehensive Services for Industry: Automation, Gas Detection and Flow Measurements

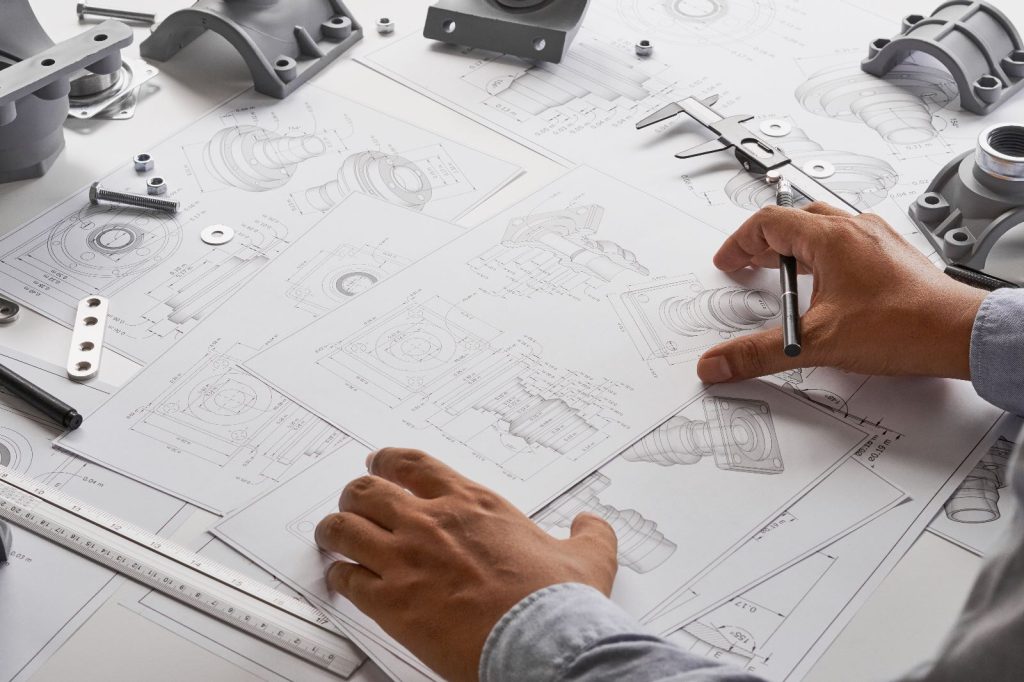

Professional Design Services: Automation and Installation Systems in EU GMP

We provide design services for all areas of production and technology. We tailor solutions to the individual needs and capabilities of our customers. We provide support throughout the entire investment phase, from concept to commissioning and subsequent service supervision.

Our staff has more than 15 years of experience in the EU GMP environment, both in design of systems and installations, supervision of their implementation, as well as subsequent use and service. We also provide support in carrying out qualification of the described systems and installations.

We offer:

- Design of electrical installations, AKPiA,

- design of prototype machines,

- design of production lines,

- design of installations and measuring systems and their programming,

- design of industrial control systems,

- programming of PLCs,

- programming of operating panels,

- programming of industrial process visualisation systems,

- specialised software development.

Service checks of stationary hazardous gas detection and monitoring sensors

Thanks to modern measuring instruments, we perform the most advanced verification of metrological data, in accordance with accepted national and international methods. The quality of the measurements carried out has been repeatedly confirmed in a number of inter-laboratory comparisons, during which Introl Automation has always obtained very good results.

As part of Introl Automatyka’s maintenance services we offer:

- guarantee and garantee inspections of the detection systems we offer,

- calibration of detection systems and monitoring on site,

- calibration of the offered equipment at the premises of Introl Automatics,

- verification of operation of equipment and associated systems (ventilation injectors, communication with DCS).

Complex Gas Detection Systems: Design, Installation, Integration and Service

Introl Automatyka offers the manufacture of complete stationary detection systems and monitoring of hazardous gas concentrations. Starting from the execution of the gas design, through the selection of the solution, delivery of the system, its installation, integration with plant associated equipment, as well as complete maintenance service. As part of the gasometer projects carried out, the investor receives a complete study defining the requirements for the installation of the detection system, the project specifies its components and guidelines for the layout of the individual system components and their installation. The most important part of the gasimetric design is the opinion of fire expert guaranteeing the correctness of the design and its compliance with current regulations.

Design of detection installations:

- toxic gases,

- flammable gases,

- in the area of component tanks,

- gas boiler plants,

- in certain production processes.

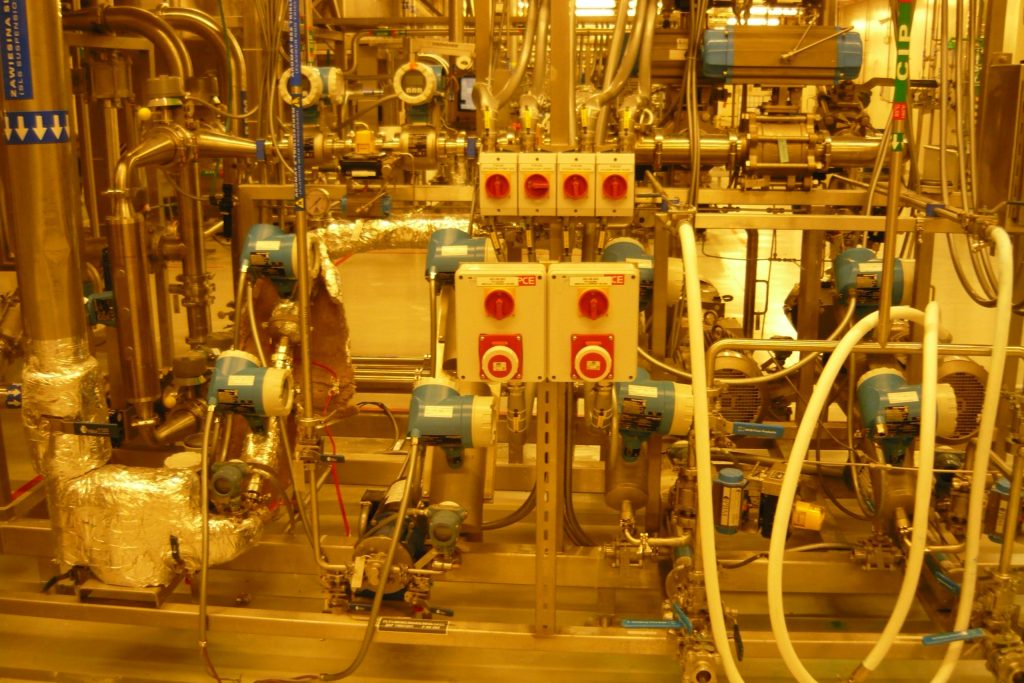

Non-invasive Flow and Energy Measurements: Pipeline Measurement Services

Non-invasive flow and energy measurements.

For many years, we have offered the pipeline flow measurement service without intervening in the pipeline walls. Only isolation of the pipeline is required. The flow meter probes using the ultrasound method calculate the flow with accuracy of up to 1%. This method saves time and money, especially with large diameters (up to DN 4000). With the non-invasive flow meter, we can also carry out the heat or cold measurement service. This measurement is made possible through the use of dedicated invasive measurement sensors. The service report is used for energy optimisation calculations for energy efficiency audits.

Non-invasive measurement allows for:

- verification of installed measuring devices,

- verification of metrological correctness,

- checking pump efficiency,

- leakage verifications of gates and valves,

- determination of utilities consumption,

- measurement of thermal energy,

- measurement of various media (water with various mixtures e.g. with glycol, oils, acids, aggressive media).

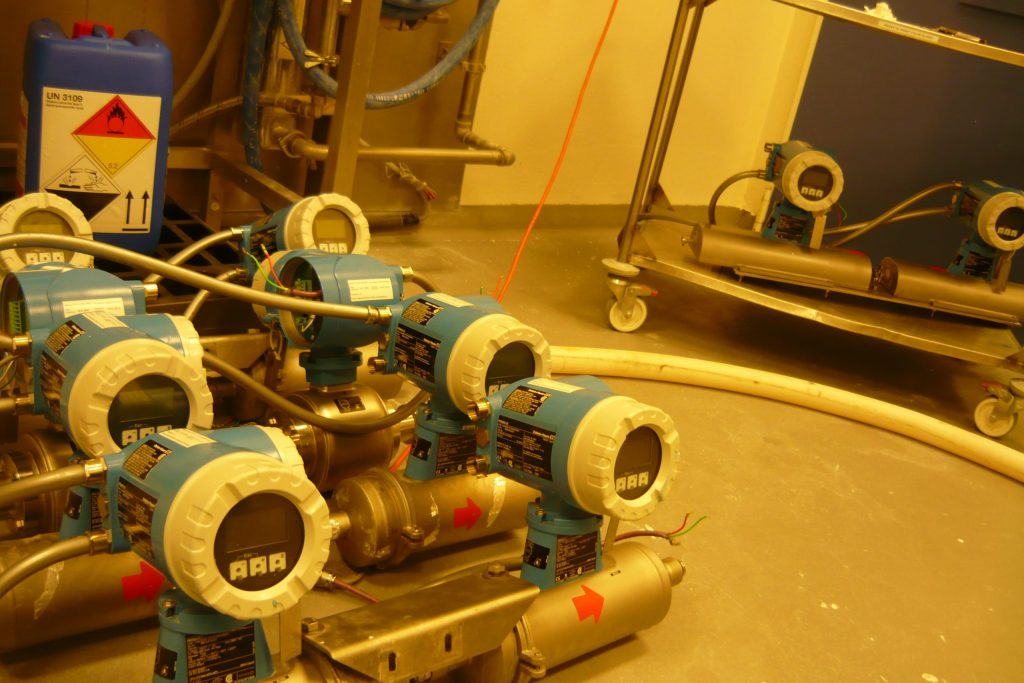

Checking of other physical quantities

We perform checking of measuring devices at the customer’s site. Using a high-quality standard, we will check the correctness of pressure, differential pressure and temperature transmitters. We also check the correctness of analogue output signals. The measuring devices can be dismantled immediately before checking and reassembled immediately after checking. This reduces downtime to the necessary minimum.

As a result of checking the equipment, you can get:

- certificate of checking, calibration at several points,

- confirmation of correctness of signals

- confirmation of range stability,

- diagnosis of potential damage,

- process optimisation.