Vacuum Transport Systems for Bulk Materials and Robotic Palletizing Stations

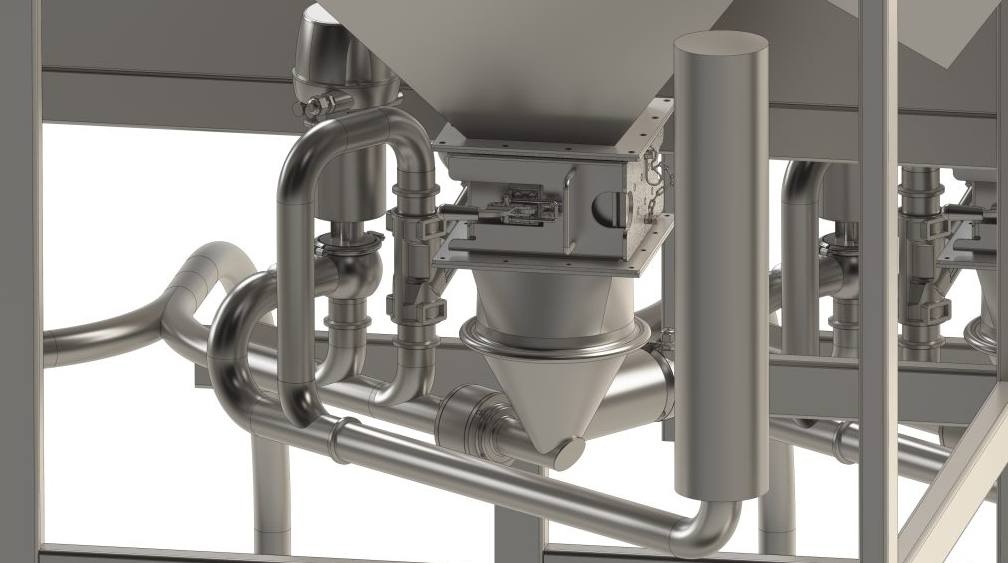

Vacuum conveyor systems for powders and bulk materials

To meet our customers’ needs related to the transport of powders and bulk materials required in production processes, we offer comprehensive transport systems based on vacuum conveyors. Our solutions provide a safe, hygienic and ergonomic working environment, resulting in high product quality and minimising the risk of loss due to spillage or damage.

Vacuum conveyors create a closed material handling system, eliminating the need for manual handling or the use of mechanical transport. Thanks to the dense transfer phase, even delicate materials such as fragile coated tablets are safe during transport, minimising the risk of product damage.

Our solutions can be easily integrated into existing systems, making efficient use of existing infrastructure. In this way, the customer can quickly introduce innovative solutions, improving the efficiency and safety of its production processes.

The offer includes:

- Interview with the client and definition of needs,

- identification of possible solutions,

- definition of a budget and deadline for implementation,

- presentation of the technical offer,

- manufacture of a complete device,

- software adaptation

- field assembly and power connection

- testing and commissioning,

- granting of a declaration of conformity,

- operator training.

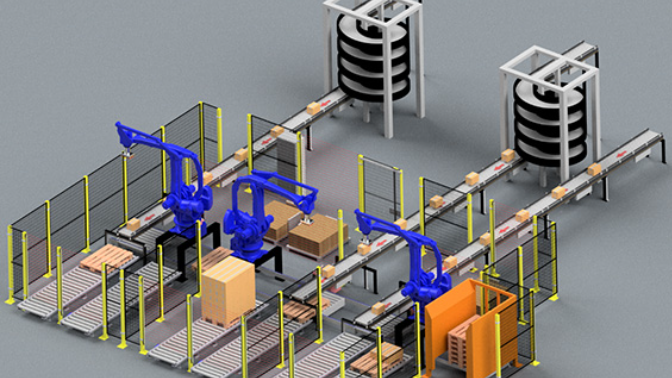

Robotised palletising and depalletising stations

The dynamic development of robotisation, not only in the field of production, but also in the area of storage, puts a premium on single stations for palletisation and depalletisation. Especially for plants with multiple production lines, it can be advantageous to concentrate the palletising process in one central station.

Centralising automated palletising has many benefits, including a significant reduction in investment costs – one robot can service several packing lines, typically up to five. Additionally, such a central robotised station ensures higher quality of the packaging process and its repeatability. Thus, the company can achieve efficiency and cost optimisation in its logistics operations.

Benefits of using robotic stations:

- increase production efficiency,

- increase packaging reliability,

- minimising the use of production space,

- optimisation of human resources,

- monitoring and recording of the packaging process,

- ensuring production continuity.