Advanced Frequency Inventers and Control-Measurement Systems for Mining, Metallurgy and the Chemical Sector

Medium voltage drives (MVD)

The MVD (Medium Voltage Drives) division has specialised for more than 15 years in the comprehensive implementation of medium voltage frequency converters and soft-start systems in advanced projects for Polish industry. Our experience includes numerous applications based on medium voltage inverters and softstarts, which contribute to the optimisation of production processes.

As pioneers on the Polish market, we realised the first application of medium voltage converters of the Allen – Bradley brand for speed control of conveyor belts. In addition, our track record includes applications using 6kV drive systems, successfully applied to exhaust fans, air fans, feedwater pumps and mains water pumps, among others. With our solutions, we provide customers with efficient and reliable drive systems that support the growth of their businesses.

- As one of only two companies in Poland, we are certified by the Power programme implemented by Rockwell Automation. We have the opportunity to carry out independent commissioning and servicing of devices such as medium-voltage frequency converters (medium-voltage inverters) and medium-voltage soft starters during their warranty period, which until now was carried out exclusively by the manufacturer,

- The Power certification in Rockwell Automation’s Recognized System Integrator partner programme is an extension of our existing cooperation in the field of control system integration, in which we have already been certified by the Control programme for many years,

- The awarding of the Power certificate to us would not have been possible without the trust of “Polish industry” and our numerous implementations in the field of medium voltage drive systems in projects (belt conveyors, exhaust fans, pumps). The trust placed in us by Rockwell Automation enables us to cooperate even better and to continuously develop by improving our qualifications,

- It is with undisguised satisfaction that we are able to appreciate the fact that contractors are able to appreciate our commitment to their projects, which offers even better opportunities for future cooperation and the winning of many contracts in the constantly growing medium-voltage drive industry.

Rockwell Automation LVD low-voltage frequency inverters

Low-voltage LVD (Low Voltage Drives) systems, i.e. frequency inverters and usoft-start systems, are key solutions for efficient operation of machinery and equipment, with attention to product safety and reliability. The systems we offer are based on key components from the Allen-Bradley brand, ensuring not only performance but also excellent durability in the harshest environmental conditions.

The LVD range includes frequency inverters from the PowerFlex AC and DC series, tailored to a wide variety of applications. The use of PowerFlex inverters guarantees cost-effective solutions for both individual machines and integrated control systems. Improved motor control efficiency and optimised motor parameters translate into higher efficiency of the entire production process. With our solutions, the customer can count on optimum use of resources and achieving the best production results.

- Safety features protecting personnel and property while reducing downtime,

- perfect integration with the Logix environment streamlining configuration and software,

- protection against unscheduled stops thanks to advanced diagnostics , and notification of unstable operating parameters,

- access to data in real time for decision-making, facilitating smooth production processes,

- reduction in maintenance and energy consumption of up to 60%,

- high reliability compared to other similar products on the market,

- highest efficiency in its class as confirmed by the international IEC 61800-9-2 standards for defining efficiency and energy efficiency for drive systems.

Yaskawa LVD low voltage inverters

Our low-voltage frequency inverters group offers specialised solutions for the control of lifting motors in equipment such as passenger lifts, goods lifts, escalators, screw feeders, winders and conveyors. With our many years of experience in industrial automation and an impressive 22 million installed lifters worldwide, our solutions are appreciated for their high quality and special design, which make them ideal for highly specialised applications.

One of our dedicated models of frequency inverters is the U1000 by Yaskawa, which is ideal for single motor drive applications that feature low harmonic distortion and generator mode capability. This model also works well in HVAC and many other applications. Thanks to the drives’ high efficiency and near unity power factor, we ensure sinusoidal input current and minimise losses in generators, transformers and power cables. This allows our solutions to optimise energy utilisation and achieve the best production results.

- The best driving comfort is provided by special control algorithms and dedicated elevator control functions,

- Fast, simplified configuration with automatic tuning at rest without the need to remove the cables, the default settings are selected to suit the needs of most installations,

- Brake monitoring as part of the protection against unintended cab movement, reducing implementation costs,

- Operation without motor contactors reduces audible noise and implementation and maintenance costs, without compromising safety conditions,

- Innovative low-voltage MATRIX technology with direct AC-to-AC energy conversion ensuring energy return to the grid even for very low drive powers (a few kW),

- Low levels of higher harmonics without the need for additional filters.

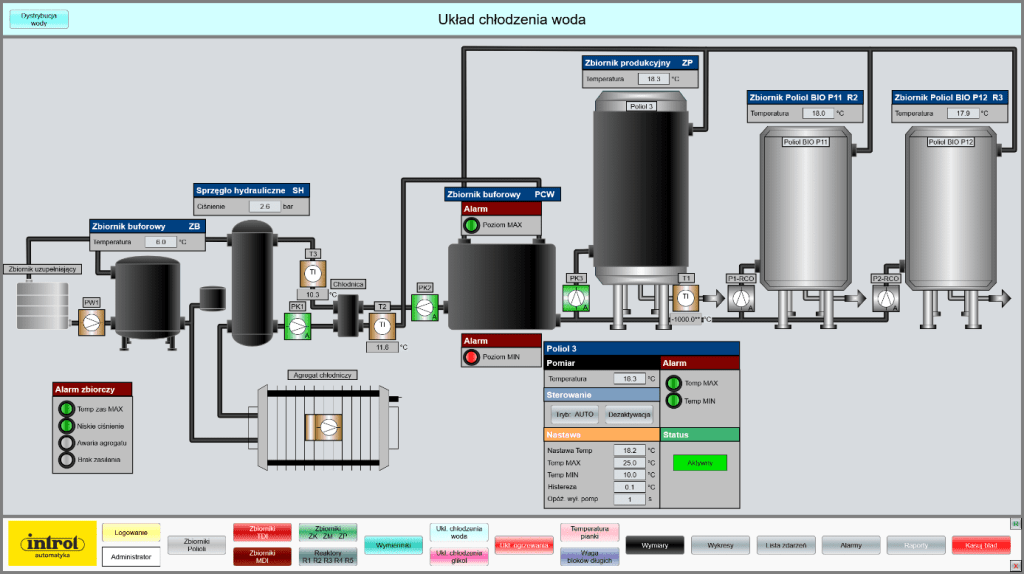

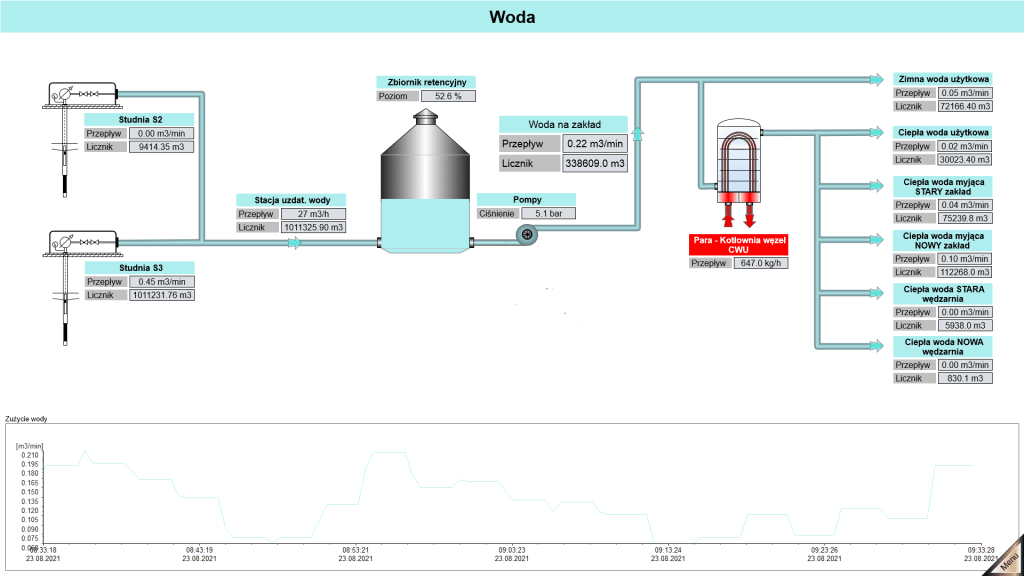

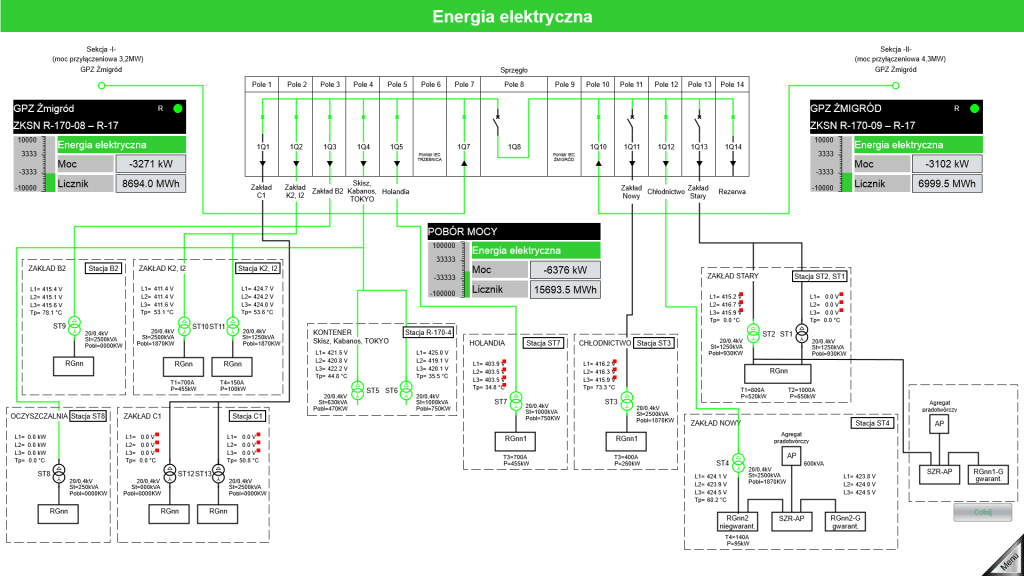

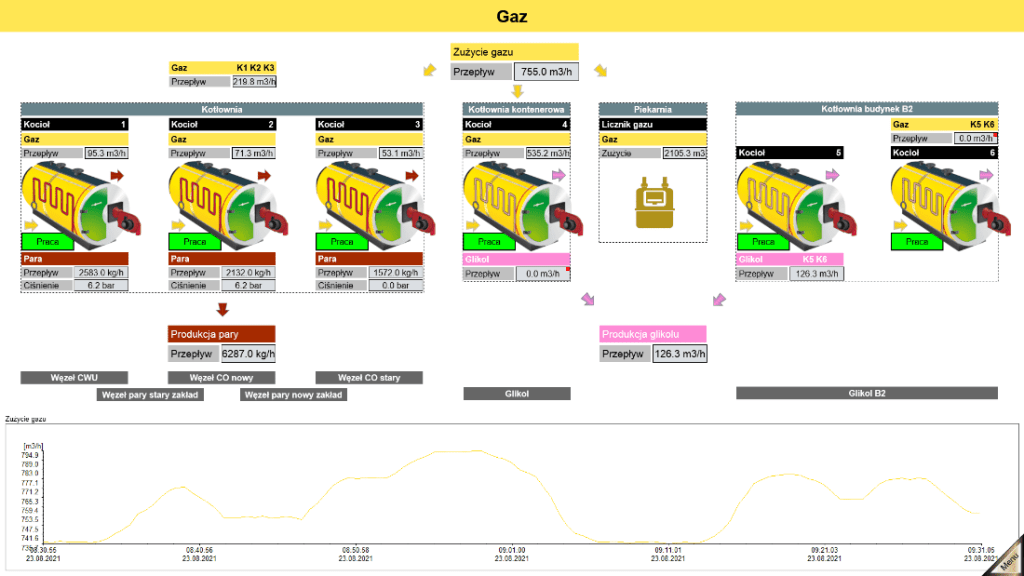

Process control and SCADA systems

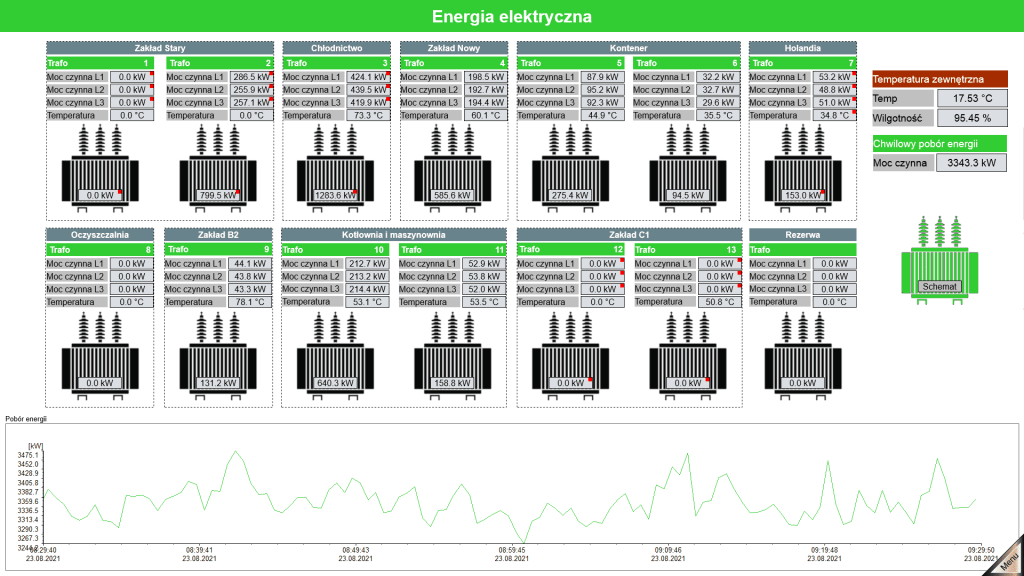

We have many years of experience in the measurement of various types of utilities and in the comprehensive implementation of utilities consumption monitoring systems. In view of the volatility of electricity and gas prices, the implementation of a system enabling the monitoring of utility consumption in a production facility becomes crucial to control fixed costs.

Our systems enable the monitoring of electricity, natural gas, compressed air, steam, heat and cooling consumption. Each application is developed from scratch and tailored to individual customer needs and expectations. Together with the client’s representatives, our engineers define the scope of the project, define milestones and establish the system concept.

During project implementation, important issues are agreed with the developer at every stage. We utilise a variety of software platforms, such as SCADA, which enables efficient use of existing equipment on site and easy integration with existing on-site systems. In this way, we provide comprehensive and customised solutions that contribute to the optimisation of utility consumption and efficient management of energy resources.

A utility monitoring system:

|

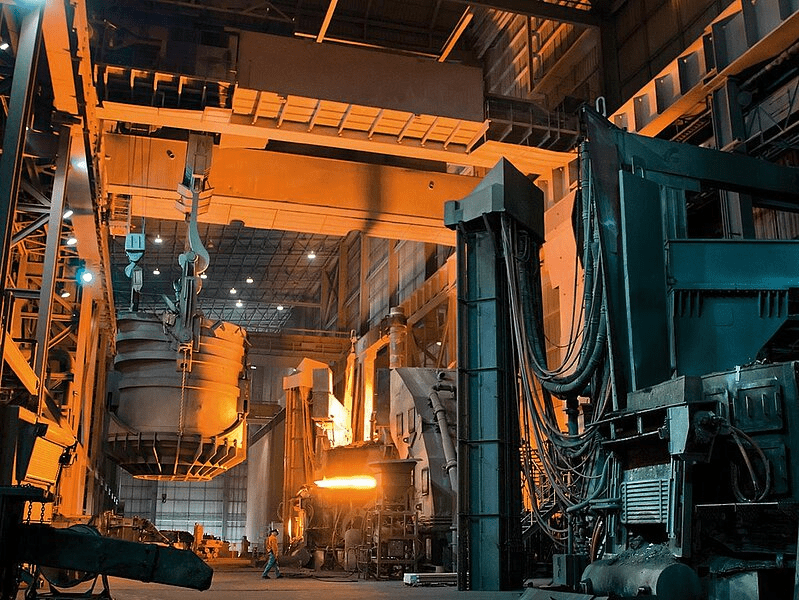

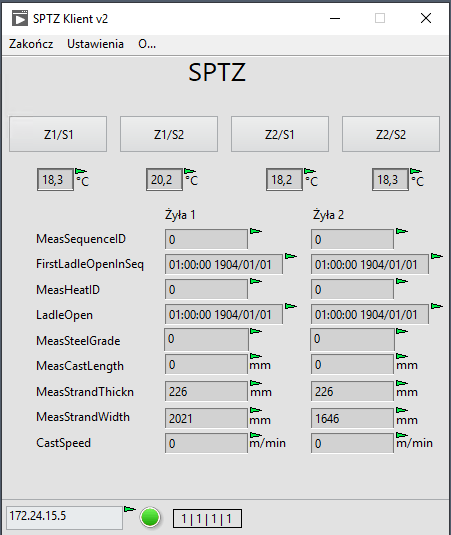

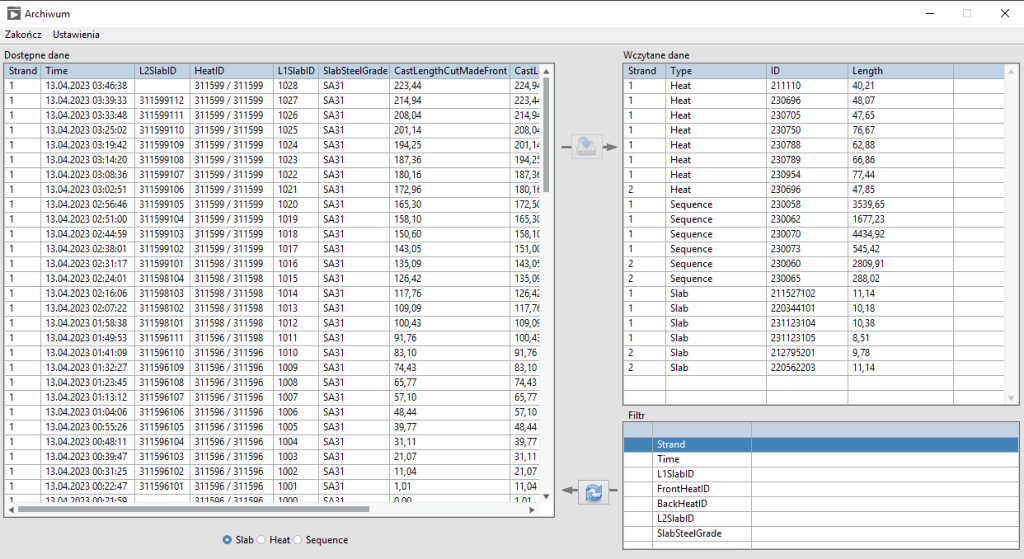

Control and measurement systems in the steel industry

In the metallurgical industry, in addition to the standard measurement of thermal energy, compressed air, fumes and other gases, Introl Automation also offers comprehensive measurement solutions. Our offerings include caloricity measurements of blast furnace gas and coke oven gas, gas detection, level measurements, temperature, physical and chemical analysis of liquids and weight measurements.

All of our measuring systems are realised comprehensively, from conception and design to the selection of suitable equipment, installation and commissioning. In this way, we provide our customers with comprehensive support and the highest quality measurement services, tailored to their individual needs and expectations.

Interesting features of measurement systems:.

- mass flow measurement – 100% diameter range,

- flue gas flow measurement with billing approval ( QAL 3 ),

- real-time data reading,

- ultrasonic non-invasive liquid measurement as an alternative to insertion measurement.

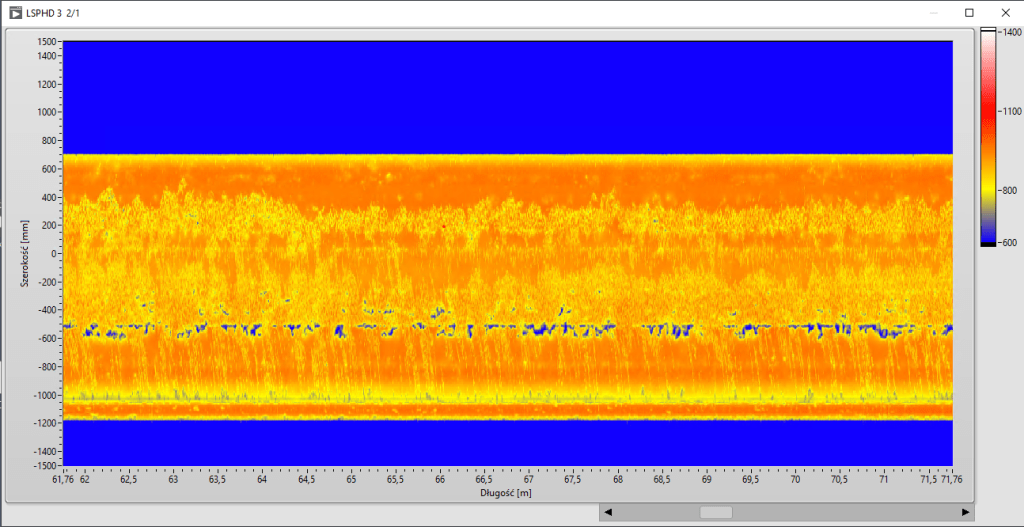

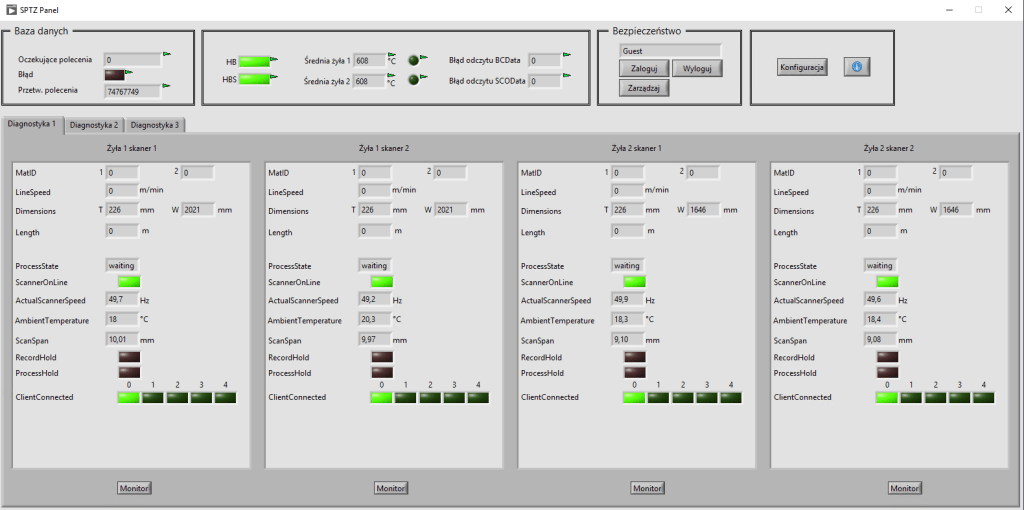

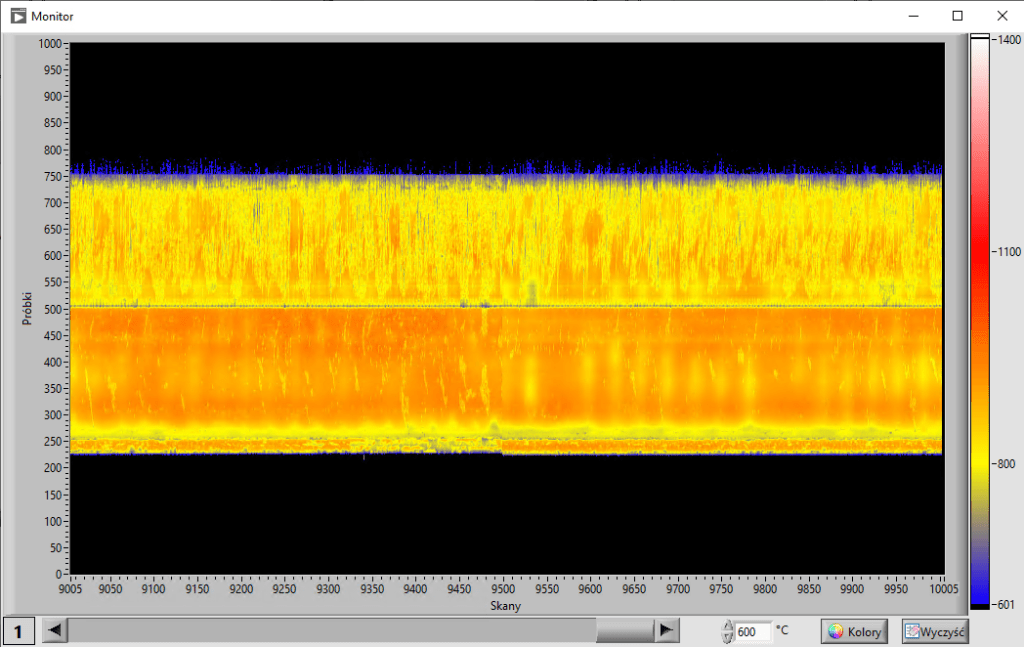

Installation of a continuous band temperature measurement system on the COS line

Installation of a distribution for measuring the surface temperature of objects in motion in the range from 50 to 350° C realised using line scanners.

System advantages:.

- dedicated solution for demanding customer needs,

- the application manages T-bytes (verification with MK),

- scanning frequency 120Hz

- detection of steel inhomogeneities,

- continuous monitoring of the quality of the steel produced, including recording,

- product quality certification.

Melted product geometry control system

In terms of its offer to the steel industry, Introl Automatics proposes a solution that enables precise measurement and control of geometric parameters of smelted billets, such as width, length and thickness. Our solution is based on the use of the system EMG iSCAN®, ensuring reliability and precision measurements. EMG iSCAN® enables the measurement of hot steel strips and plates and the non-contact measurement of plate dimensions using advanced laser sensors. With this system, geometric parameters can be accurately monitored under harsh environmental conditions, contributing to the optimisation of production processes in the steel industry.audyty

More about the system in the link:

Link to EMG – Introl Automation Partner website

Main advantages of the EMG iSCAN® system:

- possibility to visualise slab profile, edge shape and cracks,

- optimisation of the casting process,

- optimisation of the transport of the billet to the heating furnace,

- perfect positioning of the plate before further processing,

- measurement of the slab geometry on the roller table for smooth loading into the heating furnace.